SBR

Styrene-Butadiene rubber (SBR) Styrene-butadiene rubber (SBR) exhibits a structural relationship between styrene and butadiene, making it a widely used copolymer. This polymer is highly prevalent in the rubber industry due to its outstanding physical and mechanical properties. It finds applications in automotive and industrial rubber production, engineering structures, automotive manufacturing, and textiles. Key characteristics of SBR include flexibility, resistance to oil, water, and heat, as well as durability against corrosion and abrasion. Therefore, a significant portion of rubber production is dedicated to this polymer. SBR latex exhibits desirable wear resistance, with over 70% of produced SBR used in tire manufacturing, another 15% in mechanical components, and nearly 10% as latex. The ratio of styrene to butadiene can significantly influence the properties of SBR latex. Higher styrene content results in a harder rubber. SBR burns in flames and continues to burn after the flame is extinguished. Its flame appears yellow-orange and produces a slight crackling sound, emitting smoke that is whitish-gray. For more accurate information regarding prices or purchasing the product, it is better to contact the sales department of Petro Nour Mehr Company.

Styrene-Butadiene rubber Manufacturers in Iran

In the petrochemical industry of Iran, several companies and production units are engaged in the production of SBR. These companies include:

- Bandar Imam Petrochemical Company

- Takhte-jamshid Petrochemical Company

These units are among the largest SBR producers in Iran and play a significant role in supplying domestic needs and exporting this material to global markets.

Styrene-Butadiene rubber Manufacturers Worldwide

Across the globe, some major producers of Styrene-Butadiene rubber (SBR) include:

- INEOS: This company is one of the largest SBR producers in North America and engages extensively in the production and distribution of polymers and chemicals.

- Shell: Shell is also a major producer of SBR in North America with extensive activities in the production of rubber and polymer products.

- Albemarle Corporation: This company is recognized as one of the largest SBR producers in North America and is known as a leader in chemical manufacturing.

These companies are renowned as the largest SBR producers globally and have a significant impact on the polymer and rubber industries in their respective regions.

Applications of Styrene-Butadiene rubber

Styrene-Butadiene Rubber (SBR) finds widespread application across various industries due to its versatile properties. Some of the key applications of SBR include:

- Automotive Tires: SBR is extensively used in the production of automotive tires, where it provides excellent abrasion resistance, toughness, and durability. It contributes to improving the tread life and overall performance of tires.

- Footwear: In the footwear industry, SBR is used for manufacturing shoe soles and heels due to its good abrasion resistance, flexibility, and resilience. It helps in enhancing the durability and comfort of footwear products.

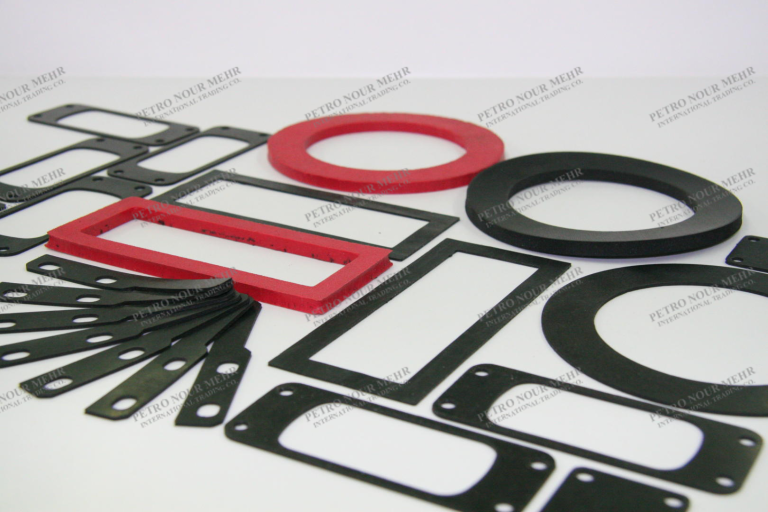

- Industrial Rubber Products: SBR is employed in a wide range of industrial rubber goods such as conveyor belts, hoses, gaskets, seals, and molded rubber parts. Its properties like good tensile strength, tear resistance, and resilience make it suitable for these applications.

- Construction Sealants and Adhesives: Due to its ability to withstand weathering, SBR is used in sealants and adhesives for construction applications. It provides effective bonding and sealing properties, making it ideal for building materials.

- Sporting Goods: SBR is used in the production of sporting goods such as balls (e.g., basketballs, soccer balls), mats, and grips. Its flexibility, resilience, and impact resistance contribute to the performance and durability of these products.

- Flooring and Matting: SBR is used in flooring materials, including tiles and mats, due to its abrasion resistance, slip resistance, and ease of processing. It is commonly found in gym flooring, playground surfaces, and industrial matting.

- Electrical Insulation: High-Styrene Resin (HSR), a derivative of SBR, is used for electrical insulation applications. It offers excellent heat resistance, electrical insulation properties, and mechanical strength, making it suitable for electrical components and cables.

- Civil Engineering: In civil engineering, SBR is used for asphalt modification to improve the properties of road surfaces. It enhances the durability, flexibility, and fatigue resistance of asphalt pavements.

- Miscellaneous Applications: SBR is also utilized in various miscellaneous applications such as molded goods, automotive components (e.g., rubber seals, gaskets), rubber rollers, and even in consumer products like rubber bands and toys.

Styrene-Butadiene Rubber (SBR) finds diverse applications across various industries, serving different purposes. Generally, SBR is utilized in industries such as rubber manufacturing, construction, civil engineering, adhesive industries, production of both rubber and non-rubber products, as well as insulation and impact-resistant materials.

These polymers are used for manufacturing consumable rubbers, asphalt and waterproof coatings, additives in concrete, adhesive products, insulation, impact-resistant materials, and more.

Additionally, they are applied in producing both rubber and non-rubber products like carpets and flooring. Overall, SBR polymers are employed as base materials or additives in the production of various products that require flexibility, durability, and high mechanical performance.

Storage Conditions for Styrene-Butadiene rubber

This polymer material can be stored under various conditions, but there are some guidelines for better preservation of their quality:

- It is best to store these materials in a cool and dry environment, with the optimal storage temperature being below 20 .

- Protect the material from direct sunlight and UV light, as these lights can cause changes in its physical and chemical properties.

- Styrene-Butadiene rubber react with certain chemicals such as solvents and acids. Therefore, it is better to avoid direct contact with these types of materials.

- Make sure the material has protection from impacts and scratches while being stored and transported, since physical harm may cause modifications to its mechanical and structural characteristics.

- The packaging of these materials should be made of suitable materials that protect against environmental changes and prevent water and moisture penetration into the packaging.

- For some specific products, special storage conditions may be required. In this case, refer to the manufacturer’s guidelines.

Packaging for Styrene-Butadiene rubber

For packaging and exporting solid Styrene-Butadiene rubber (SBR), various methods can be utilized depending on environmental conditions, product requirements, and transportation facilitation for export. Below are some common methods for packaging and exporting this polymer material:

- Packaging in Small Bags: In this method, the rubber is packed into smaller bags with a capacity of about 20 to 25 kilograms.

- Wooden Box Packaging: This is a common method for packaging SBR, where the rubber is packed inside large wooden boxes with varying capacities (typically between 500 to 2000 kilograms). These boxes provide protection against contamination and moisture, making them suitable for road, sea, and air transportation.

- Use of Pallets: SBR is usually packed on large pallets for transportation purposes.

Adherence to international packaging standards, labeling requirements, and transportation conditions can significantly impact the choice of suitable packaging and export methods for SBR. It is also crucial to ensure protection of the product against shocks, moisture, and environmental damage during transportation.

Advantages and Disadvantages of Styrene-Butadiene rubber

SBR is a synthetic polymer widely used in various industries, exhibiting both advantages and disadvantages that impact its position and applications. Among its advantages are high physical resistance, adequate flexibility, and resistance to weathering. These properties make SBR suitable for producing tires, waterproofing materials, and foam products.

However, SBR is sensitive to heat and can lose its shape at high temperatures. Additionally, its deformation capability and drying time are considered drawbacks, requiring careful handling in diverse industrial applications. Overall, the use of SBR, considering its pros and cons and specific application conditions, can enhance the performance and efficiency of final products.

Styrene-Butadiene latex is a polymer with numerous advantages utilized across many applications. These advantages include high-quality resistance to cracking, abrasion, and wear, adequate resistance to corrosion and chalking, suitable flexibility at low temperatures, heat and impact resistance, outstanding physical and mechanical properties, and desirable electrical characteristics.

Furthermore, its benefits extend to minimal color change, ideal thermal aging resistance, and excellent resistance against polar solvents, dilute acids, water, and sunlight. However, like any material, this polymer has limitations and disadvantages that require attention, such as low resistance to ozone and flames, challenging processing, poor resistance to gasoline and oils, and susceptibility to hydrocarbon solvents.

Physical and Chemical properties of SBR:

SBR possesses a diverse range of physical and chemical properties that make it a popular and widely used polymer. Here are some of its key properties:

- SBR exhibits high flexibility, making it suitable for applications such as the production of rubbers and flooring materials.

- This polymer has good abrasion resistance, which ensures longer durability of rubber and other products made from it.

- SBR typically shows decent resistance to corrosion, making it suitable for applications like concrete reinforcement.

- This polymer is composed of a blend of styrene and butadiene, which imparts specific properties such as flexibility, corrosion resistance, and wear resistance.

- SBR processes and forms well, making it useful in industrial processes and the production of various products.

- SBR generally exhibits good chemical stability, making it suitable as a base material in various chemical compounds.

With these properties, SBR is recognized as a versatile polymer with numerous applications across different industries. It is used as a cost-effective substitute with comparable performance to natural rubbers. Overall, SBR offers high flexibility, resistance to abrasion and corrosion, and favorable chemical properties, making it widely used in industries including rubber, construction, and automotive sectors.

Types of SBR grades:

Styrene-Butadiene Rubber (SBR) grades can be classified into several types based on their composition, polymerization method, and intended applications. Here are the main kinds of SBR grades:

- Emulsion SBR (ESBR):

- Produced through emulsion polymerization.

- Typically used in applications requiring good abrasion resistance, flexibility, and resilience.

- Commonly found in automotive tires, conveyor belts, footwear, and various industrial rubber products.

- Solution SBR (SSBR):

- Produced via solution polymerization.

- Offers superior processability and can be tailored for specific performance characteristics.

- Used in high-performance applications such as tire treads, specialty footwear, and industrial rubber goods requiring enhanced mechanical properties.

- High Styrene SBR (HS-SBR):

- Contains a higher styrene content compared to standard SBR.

- Provides improved stiffness, hardness, and abrasion resistance.

- Often used in tire sidewalls, shoe soles, and applications needing greater durability and resilience.

- Oil-Extended SBR (OE-SBR):

- Modified with oil to improve processability and performance.

- Offers enhanced resilience and abrasion resistance.

- Used in molded rubber products, automotive components, and general industrial applications.

- Cold SBR (CR-SBR):

- Designed for applications requiring resistance to low temperatures.

- Maintains flexibility and elasticity at cold temperatures.

- Used in seals, gaskets, weatherstripping, and other cold-resistant applications.

- High-Styrene Resin (HSR):

- A thermoplastic resin derived from styrene and butadiene.

- Provides excellent heat resistance, hardness, and electrical insulation properties.

- Utilized in electrical insulation, automotive parts, and other specialized applications.

These various types of SBR grades cater to specific industrial needs, offering a range of properties such as flexibility, resilience, abrasion resistance, heat resistance, and environmental durability. Manufacturers select the appropriate grade based on the requirements of their end products and the conditions in which they will be used.

How to Buy Polyethylene?

- Buy from a reputable and authorized supplier that holds necessary certifications and guarantees quality.

- Compare the prices of these materials in different markets and compare them with the global market price.

- Examine the sales conditions regarding quantity, delivery time, packaging, transportation methods, and payment terms.

- If you intend to import polystyrene from foreign countries, investigate customs and legal regulations and comply with export and import regulations.

- Contact bravopolymer to obtain the most suitable export price based on your conditions.

- After signing the contract, you can place your order.

- Secure and suitable payment methods according to customer preferences are provided by the company.

- Then, the loading stage is completed by selecting and introducing a transport company.

- Necessary documents for customs clearance at the destination city are also provided to customers by bravopolymer.

The largest distributor of polymers in the Middle East