PEG 400

PEG 400 (Polyethylene glycol 400)

Polyethylene glycol 400 is a chemical compound belonging to the family of polyethylene glycols. This substance is used as a solvent, diluent, and heat transfer agent. Additionally, it finds applications in pharmaceuticals, food industry, coatings, ceramics, electronics, and more. PEG 400 exhibits good solubilizing properties for pharmaceuticals and environmental non-toxicity, which are utilized in pharmaceutical manufacturing processes. Moreover, this substance has a density of 1.13 gr/cm3.

Polyethylene glycols are derived from the oxidative polymerization of ethylene oxide with monoethylene glycol or diethylene glycol. The general formula for polyethylene glycol is represented as H(OCH2CH2)nOH, where n denotes the average number of ethylene oxide groups. Different grades of polyethylene glycol are characterized based on their average molecular weight.

For example, PEG400 contains a distribution of chains with an average molecular weight of 400, similarly, the approximate average number of ethylene oxide repeating groups is 9.

For more accurate information regarding prices or purchasing the product, it is better to contact the sales department of Petro Nour Mehr Company.

PEG 400 Manufacturers in Iran

Shazand Arak Petrochemical and other domestic factories are producers of this polymer material in Iran.

These units are among the largest PEG400 producers in Iran and play a significant role in supplying domestic needs and exporting this material to global markets.

PEG 400 Manufacturers Worldwide

Major PEG 400 manufacturers worldwide include:

In the continent of America, there are numerous companies manufacturing polyethylene glycol (PEG). Some of these companies include:

- Dow Chemical Company: One of the largest chemical producers globally with manufacturing units in North America.

- BASF: A German chemical company with active branches in America, producing PEG and other chemical substances.

- Ineos: A major chemical company involved in the production of PEG and other chemical products.

These are just a few examples of PEG manufacturers in America, as there are many other companies active in this industry. These manufacturers are just a few examples of companies worldwide that produce polyethylene glycol 400. Additionally, there are other companies active in this industry, producing various types of this polymer substance.

Applications of PEG 400

PEG400 is a non-toxic and harmless polymer that is widely used as an adhesive and additive in many industries. Due to its various properties, including adhesion, stability, water absorption capability, and human safety, it finds applications in various fields. Some of the chemical’s applications include:

- Cosmetic and Personal Care Industries: PEG 400 is utilized in cosmetic and personal care products such as moisturizing creams, lotions, hair care products, as a moisturizing, softening, surfactant, and emulsifier agent. Additionally, it is used in softening creams, shampoos, conditioners, sunscreens, nail polishes, and hair dyes.

- Chemical Industries: PEG 400 readily dissolves chemicals and serves as an effective tool in chemical processes such as color production, pharmaceuticals, and plastics. It acts as a solvent, aiding in the dissolution of dyes in colors, resulting in uniform and attractive colors. Moreover, it can assist in uniform distribution of chemicals, especially in industries like paints, coatings, where uniform dispersion of pigments is required. Its usage in lubricants, greases, and lubricants reduces friction between moving parts, increasing their lifespan.

- Textile Industries: PEGs act as softeners and antistatic agents in the textile industry, aiding in softening fabrics. It is often used in cotton, wool, and silk fabrics. Additionally, PEG helps in maintaining moisture in fabrics, preventing wrinkles in cotton and polyester fabrics.

- Food Industries: PEGs serve as a food additive and preservative, preventing microbial growth in food items, dissolving active ingredients in food, and thickening them. It is commonly used in dairy products, breakfast cereals, beverages, sauces, desserts, and ice creams, as well as herbal medicines and dietary supplements.

- Pharmaceutical Industries: PEGs are used as a solvent, permeation enhancer, and adhesive agent in drugs. These substances protect drugs from digestion and aid in their absorption into the body. They are commonly used in oral, injectable, and topical drugs, as well as liquid drugs, gels, and ointments.

Storage Conditions for PEG 400

Storage conditions for PEG 400 may vary depending on its type and intended use. However, generally, the typical storage conditions for this chemical compound are as follows:

- The suitable temperature for storing this chemical compound is usually within the room temperature range (approximately 20-25 degrees Celsius). However, it’s essential to follow the specific guidelines provided by the manufacturer, as some products may require a specific temperature for storage.

- PEG 400 should be protected from direct sunlight and UV light. Therefore, it is best to store it in a dark environment away from direct sunlight.

- Typically, this chemical compound is stored in a dry and cool environment. Some products may even require storage in a moisture-free environment.

- For some specific cases, special storage conditions may be required. In such cases, refer to the manufacturer’s instructions.

- Proper packaging is also of utmost importance. Generally, PEG 400 is stored in sturdy and appropriate plastic or metal drums that prevent air and moisture penetration.

- Ensure proper ventilation when using this chemical compound in confined spaces. When exposed to high concentrations of PEG 400 vapors, use appropriate respiratory protection such as a mask and suitable clothing.

- In case of skin contact, immediately wash with soap and water. Never use solvent solutions such as acetone or benzene to remove this substance from the skin.

- When using PEG 400 in hazardous environments or specific industries such as oil and gas, alcohols, etc., refer to Material Safety Data Sheets (MSDS) and relevant guidelines.

- When using this chemical compound in environments where potential interactions with other substances exist, conduct a thorough review and study of their chemical properties.

- If PEG 400 is used for food and pharmaceutical applications, always adhere to relevant standards and guidelines and assess possible interactions with additives and other drugs.

Using PEG 400 with caution and with a complete understanding of its properties and safety considerations can minimize risks. In any case, the most important reference is always the instructions provided by the product’s manufacturer and relevant standards.

It should be noted that these descriptions are general and storage conditions may vary depending on the type and use of polyethylene glycol, so always pay attention to the instructions on the product packaging and manufacturer’s guidance.

Packaging for PEG400

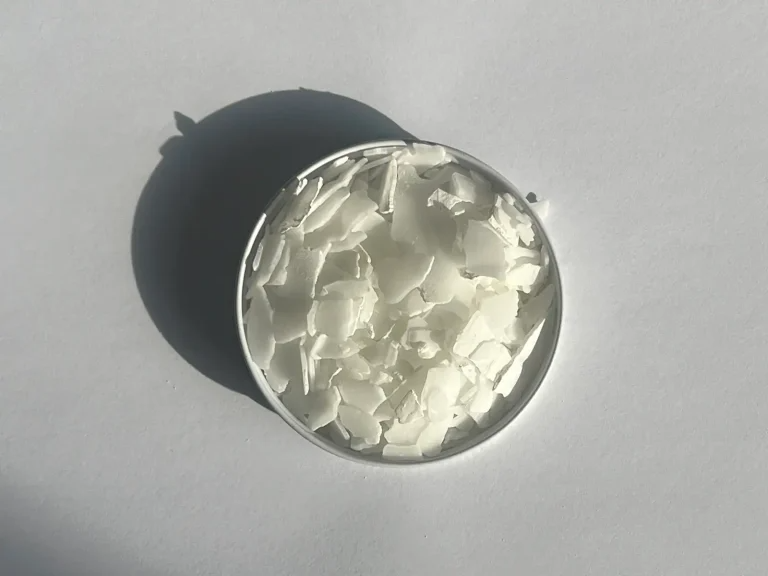

Liquid form of PEGs (200 to 1000) are packed in 220 lit (net: 200 Kg) drums, each 4 drum strapped of a pallet. Solid form (up to PEG 1000) packed in Bag (net: 25 Kg) The PEG products have shelf life of 24 months from the date of manufacture & maintained in adequate storage condition. Shelf life of pharmacy grades is 12 months.

Regardless of the packaging type, it is essential to ensure that the containers are clean, properly sealed, and labeled with relevant information such as product name, concentration, batch number, expiration date, safety instructions, and handling precautions. Proper handling and storage procedures should also be followed to maintain the integrity and stability of the PEG product.

Advantages and Disadvantages of PEG 400

The advantages and disadvantages of PEG 400 (polyethylene glycol 400) are as follows:

Advantages:

- Versatility: PEG 400 is a versatile compound used in various industries such as pharmaceuticals, food, cosmetics, and industrial applications.

- Solubility: It has excellent solubility in water and many organic solvents, making it suitable for use as a solvent or carrier for various substances.

- Non-toxicity: PEG 400 is generally considered safe for use in pharmaceuticals, cosmetics, and food products, as it is non-toxic and non-irritating.

- Stability: It exhibits good chemical stability, maintaining its properties under various environmental conditions.

- Low volatility: PEG 400 has a low vapor pressure, reducing the risk of evaporation and ensuring stability in formulations.

- Lubricating properties: It can act as a lubricant, improving the flow properties of formulations in pharmaceutical and cosmetic products.

Disadvantages:

- Hygroscopicity: PEG 400 has a tendency to absorb moisture from the air, which can lead to changes in viscosity and affect the stability of formulations.

- Potential skin irritation: While PEG 400 is generally considered safe, some individuals may experience skin irritation or allergic reactions upon contact.

- Interference with drug absorption: In some cases, PEG 400 may interfere with the absorption of certain drugs, affecting their efficacy.

- Environmental concerns: PEG 400 is not readily biodegradable, which may raise environmental concerns regarding its disposal and potential accumulation in the environment.

- Cost: Depending on the application and purity requirements, PEG 400 may be relatively expensive compared to other compounds used for similar purposes.

Overall, while PEG 400 offers many advantages such as versatility and solubility, it is essential to consider its potential drawbacks and suitability for specific applications.

Physical and Chemical Properties of PEG400

The physical and chemical properties of polyethylene glycol 400 (PEG 400) are as follows:

- PEG 400 is a clear liquid, indicating that it appears in a pure state without any sedimentation or cloudiness. Additionally, it is colorless and odorless, allowing it to be used in industrial and pharmaceutical applications without altering the color or odor of the products.

- Its viscosity refers to its specific density and fluidity, which may vary depending on environmental conditions. In other words, its viscosity may change based on temperature and pressure.

- As a solvent, PEG 400 exhibits suitable solubility properties and dissolves in water and many other solvents such as acetone, alcohols, benzene, glycerin, and hydrocarbons.

- This substance demonstrates good chemical stability, allowing it to remain stable under various conditions and be used for extended periods.

- PEG 400 can act as a surfactant and coating agent.

- It possesses good thermal stability, making it useful in the production of certain products and industrial processes.

- Polyethylene glycol 400 is a hydrophilic type of PEG with a low molecular weight. It has properties such as high solubility in water, non-toxicity, harmlessness, and compatibility with various substances.

Overall, due to its unique physical and chemical properties, PEG 400 is widely used in various industries including pharmaceuticals, food industry, chemical and petrochemical industries, electronics, and more.

Comparison of Different Types of Polyethylene Glycols:

Comparison of various types of PEGs in terms of physical and chemical properties can be as follows:

- Chemicals with lower molecular weights are commonly used as solvents and plasticizers, while higher molecular weight PEGs are used as drugs and surface coatings.

- Polyethylene glycols with lower molecular weights dissolve well in water and are used as solvents in pharmaceutical processes and food industries, whereas those with higher molecular weights are less soluble in water and are mostly used as emulsifiers and coatings.

- PEGs with higher molecular weights typically have higher viscosity, which is useful in applications such as adhesive and coating industries.

- The chemical stability of these chemicals varies depending on the molecular weight and environmental conditions, but generally, they exhibit good stability under various conditions.

- The price of PEGs depends on their molecular weight, purity, and intended use. Chemicals with higher molecular weights usually have higher prices.

In general, choosing the appropriate type of these chemicals for each specific application depends on the required properties, environmental and process conditions, and other factors that need to be carefully examined.

How to Buy Polyethylene?

- Buy from a reputable and authorized supplier that holds necessary certifications and guarantees quality.

- Compare the prices of these materials in different markets and compare them with the global market price.

- Examine the sales conditions regarding quantity, delivery time, packaging, transportation methods, and payment terms.

- If you intend to import polystyrene from foreign countries, investigate customs and legal regulations and comply with export and import regulations.

- Contact bravopolymer to obtain the most suitable export price based on your conditions.

- After signing the contract, you can place your order.

- Secure and suitable payment methods according to customer preferences are provided by the company.

- Then, the loading stage is completed by selecting and introducing a transport company.

- Necessary documents for customs clearance at the destination city are also provided to customers by bravopolymer.

The largest distributor of polymers in the Middle East