NP

Normal Paraffin (NP)

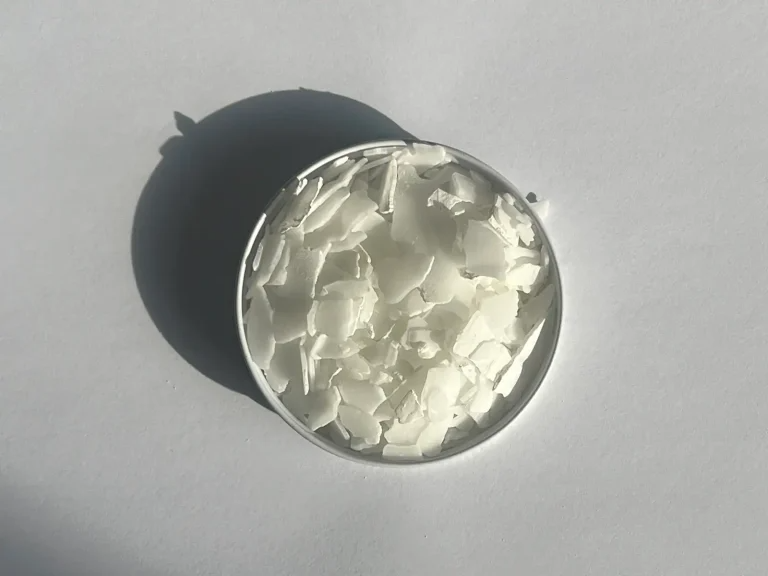

NP is a chemical compound composed of a complex mixture of aliphatic hydrocarbons (without double bonds). This mixture consists of saturated hydrocarbons formed from carbon chains and the chemical formula is CnH2n+2, where n is between 22 and 27 where n is the number of carbon atoms in a given molecule. It have straight carbon chains in their molecular structure, meaning each carbon chain is directly connected to an initial and a terminal carbon atom.

Additionally, its molecular weight is 256 gr/mol, and its density is 0.789 gr/cm3. Normal paraffin is extracted from white oil. This type of paraffin typically contains 20 to 25 percent paraffin on average. More than 80 percent of this normal paraffin is used for LAB production.

Normal paraffins are used as primary agents in the production of candles and skin creams.

For more accurate information regarding prices or purchasing the product, it is better to contact the sales department of Petro Nour Mehr Company.

Normal Paraffin Manufacturers in Iran

Iran chemical industries and other domestic factories are producers of this polymer material in Iran.

These units are among the largest normal paraffin producers in Iran and play a significant role in supplying domestic needs and exporting this material to global markets.

Normal Paraffin Manufacturers Worldwide

Major NP manufacturers worldwide include:

Throughout the world, the United States and Canada are generally recognized as the two major producers of normal paraffin. In this regard, some of the most reputable manufacturers of normal paraffin worldwide include:

- ExxonMobil: This large oil company, headquartered in the United States, is considered one of the largest producers of normal paraffin in America.

- Calumet Specialty Products Partners: This company, also based in the United States, is active in the production of petrochemical and oil products and is one of the producers of normal paraffin in America.

- Petro-Canada Lubricants: This Canadian company, a division of Suncor Energy, is also active in the production of oil products and greases and is recognized as a reputable producer of normal paraffin in the Americas.

This list is just a few examples of reputable normal paraffin manufacturers in the world, and there are many other companies in this region that are active in this industry.

Applications of Normal paraffin

Some of the applications of this compound include:

- Cosmetic and Personal Care: The use of NP in the production of cosmetic and personal care products is common, and this substance is used in these industries due to its desirable properties. These properties include softening, moisturizing, and forming a protective barrier on the skin. Some uses of cosmetic paraffin include producing cosmetic items such as eyebrow pencils and colored pencils, use for beauty and therapeutic purposes, producing skin softening creams, and serving as a moisturizing agent in the production of cosmetic and personal care products such as Vaseline.

- Candle Making: The use of paraffin dates back to ancient times when it was used to make candles. The use of NP in this field became prevalent due to the absence of toxic substances produced when burning. With its low melting point, paraffin quickly melts and solidifies rapidly after heat removal, making it suitable for making quality candles. Additionally, this substance can dissolve various colors, allowing for the production of candles in various colors.

- Lubrication: Lubricants are substances used to reduce friction between moving surfaces and make the movement of movable surfaces simpler and smoother. These compounds are usually used in the production of lubricating oils. For example, in lubricating bicycle chains or machine belts, these compounds can be used.

- Food Industry: The use of NP in the cosmetic and personal care industries is one of the important uses of this substance. For use in these industries, food-grade and completely pure grades are used. Additionally, normal paraffin is also used in the food industry for various purposes. For example, food-grade paraffin is used as a coating for some cheeses, in the production of various gums, packaging of food products, sealing some cans or bottles, and other uses.

- Industry: Various industrial paraffins are used in various industrial processes, and this substance is used in various fields. For example, in casting, production of stationery such as wax crayons, waterproofing tools such as surfboards and commercial boats, ink production, rubber industries to prevent tire cracking, sculpture, garment coating, and production of waterproof papers are among the uses of paraffin in various industries.

In general, normal paraffin is a versatile substance used in various industries including cosmetics, personal care, food, and automotive. It is used to produce lotions, skin creams, cosmetic candles, and to coat food products such as cheeses and gums. It is also used in lubrication, packaging, and preventing corrosion of automotive parts.

Storage Conditions for Normal Paraffin

The storage of NP depends on its type and form, but in general, common storage conditions for this substance include:

- It is ideal to keep these materials dry and cool; a temperature between 15-20 degrees Celsius is preferable for storage.

- Keep this material out of direct sunlight and ultraviolet light, since these sources of light may alter its chemical and physical characteristics.

- These substances react with acids and solvents, among other compounds. It is therefore recommended to stay away from direct contact with these kinds of compounds.

- During storage and transportation, ensure that this material is protected from scratches and impacts, as physical damages can lead to changes in its structure and chemical properties.

- Packaging for this grade should be made of suitable material to protect it from environmental changes and reduce the penetration of water and air into the packaging.

- Certain items can need particular storage conditions. Consult the manufacturer’s directions in this situation.

Packaging for Normal Paraffin

Packaging of NP typically varies depending on the type and application of the product. However, in many cases, NP is packaged in ready-made containers, including:

- Liquid normal paraffin is usually packaged in metal or plastic drums ranging in capacity from 20 liters to 200 liters. These drums generally have secure and tight lids to prevent leakage and spillage.

- Some normal paraffins intended for use in specific industries such as cosmetics and personal care are packaged in special containers labeled with appropriate markings and labels.

- For normal paraffin products with special applications such as medical use, special sterile packaging may be used to maintain hygiene and product quality.

Generally, NP is packaged in new or second-hand drums weighing 180 to 200 kilograms, as well as in ISO tanks and flexi tanks. The capacity of each 20-foot container for transporting NP is 110 drums.

The packaging of NP should be designed to prevent the entry of air, moisture, and harmful external radiation and preserve the quality of the product until consumption. Additionally, adhering to international packaging standards, labeling, and transportation conditions can be effective in selecting the appropriate packaging and exporting NP. It is also important to emphasize the protection of the product against shocks, moisture, and environmental damage during transportation.

Advantages and Disadvantages of Normal Paraffin

NP, with its suitable physical and chemical properties, has both advantages and disadvantages. Among the advantages, its viscosity and density are noteworthy, making it highly useful in various applications including cosmetics, hygiene, and pharmaceutical industries. Additionally, its thermal and oxidative stability prevents the absorption of nutrients and avoids adverse effects on the body. Another advantage is the colorlessness and odorlessness of many grades of NP, making them suitable for use in hygiene and cosmetic products.

However, alongside these advantages, long-term and improper use of normal paraffin may cause skin irritation, inflammation, hinder the absorption of certain nutrients, and trigger allergic sensitivities. Therefore, before using this substance, it is necessary to carefully consider the conditions of use and individual sensitivities.

Physical and Chemical Properties of Normal Paraffin

The physical and chemical properties of NP (also known as n-paraffin) include:

Physical Properties:

- State: Normal paraffin is typically found in a solid state at room temperature but can also exist as a liquid or gas depending on its molecular weight and environmental conditions.

- Melting Point: The melting point of normal paraffin varies depending on the length of its carbon chain. Generally, longer carbon chains have higher melting points.

- Boiling Point: Similarly, the boiling point of normal paraffin increases with the length of its carbon chain.

- Density: Normal paraffin has a density ranging from 0.7 to 0.9 grams per cubic centimeter, depending on its specific molecular structure.

- Solubility: Normal paraffin is insoluble in water but soluble in nonpolar solvents such as hexane, benzene, and chloroform.

- Odor: Pure normal paraffin is odorless, although impurities may impart a slight odor.

Chemical Properties:

- Combustibility: NP is combustible and burns in the presence of oxygen to produce carbon dioxide and water vapor.

- Reactivity: Under normal conditions, normal paraffin is relatively unreactive. However, it can undergo various chemical reactions such as combustion, halogenation, and oxidation under specific conditions.

- Stability: NP is stable under normal storage and handling conditions but may react with strong oxidizing agents or undergo polymerization under extreme conditions.

- Chemical Structure: NP molecules consist of linear chains of carbon atoms bonded together with single covalent bonds, with hydrogen atoms attached to each carbon atom. The general formula for normal paraffin is CnH2n+2, where “n” represents the number of carbon atoms in the chain.

- Boiling Point Distribution: Normal paraffin mixtures often have a broad boiling point distribution due to the presence of various chain lengths within the mixture, ranging from shorter chains with lower boiling points to longer chains with higher boiling points.

Overall, NP exhibits typical physical and chemical properties of alkanes, which are hydrocarbons characterized by single covalent bonds between carbon atoms.

Types of Normal Paraffin grades

- Industrial Paraffin: This type, with a carbon range of C10 to C13, is used for the production of linear alkylbenzene (LAB). Additionally, industrial grade normal paraffin is employed in the production of fatty alcohols and solvents for the paint and resin industries.

- Food-Grade Normal Paraffin: This type of paraffin, known as liquid paraffin or paraffin syrup in the market, is particularly used in the treatment of constipation in children and adolescents. However, the use of liquid normal paraffin may lead to issues such as interference with the absorption of certain drugs and vitamins in the body.

The reality is that the food-grade status of paraffin should not be seen as a reason for its extensive use in food products. Paraffin has a high heat capacity, which is why it is commonly used in cooking oils, leading to reduced production costs. However, the use of paraffin in cooking oils may inadvertently cause problems such as deposits in blood vessels and increased cardiovascular diseases. It’s better to use organic oils for daily cooking and salad preparation to avoid issues related to paraffin.

- Therapeutic Hygienic Paraffin: This type of paraffin is used in the production of cosmetic and hygienic products, and some softening creams contain this type. This substance melts at a lower temperature than room temperature and does not cause burns or blisters when it comes into contact with the skin. However, sensitive skin may become irritated upon contact with this substance, leading to redness and swelling. Therefore, it is recommended that individuals with sensitive or wounded skin avoid using paraffin altogether, as paraffin is a petroleum derivative and may cause discomfort and inflammation in the skin.

One of the grades of NP produced is of the therapeutic type. If you use therapy paraffin at home, it is advisable to avoid heating it too much as it may cause fire. For home treatment use, it is better if the temperature of the paraffin is not higher than 50 .

Therapeutic paraffin can be used for cleaning skin pores, reducing wrinkles, moisturizing, and rejuvenating the skin. Liquid paraffin has an oily form and is produced artificially through petrochemical industries, and it is considered a hydrocarbon fat substance.

Finally, it should be noted that unlike many oils, NP is not derived from plants and is therefore unnatural and may also have adverse effects and hazards.

Comparison of different grades of Normal Paraffin

Different grades of NP are defined based on their physical, chemical, and various applications. The first grade is medical grade, which has very high purity and is used as a primary ingredient in the production of medical and hygiene products. This type of paraffin must have high-quality raw materials and is suitable for applications such as disinfectant bands and skin creams. Industrial grade, which has lower quality, is used as a cheaper alternative for industrial applications such as lubrication and protective materials.

Finally, cosmetic grade has medium purity and is used for the production of cosmetic and hygiene products such as skin creams and lotions. This grade must have minimal harmful ingredients for the skin and is commonly used in cosmetic products. The choice of the appropriate grade depends on the consumption needs and desired standards.

How to Buy Polyethylene?

- Buy from a reputable and authorized supplier that holds necessary certifications and guarantees quality.

- Compare the prices of these materials in different markets and compare them with the global market price.

- Examine the sales conditions regarding quantity, delivery time, packaging, transportation methods, and payment terms.

- If you intend to import polystyrene from foreign countries, investigate customs and legal regulations and comply with export and import regulations.

- Contact bravopolymer to obtain the most suitable export price based on your conditions.

- After signing the contract, you can place your order.

- Secure and suitable payment methods according to customer preferences are provided by the company.

- Then, the loading stage is completed by selecting and introducing a transport company.

- Necessary documents for customs clearance at the destination city are also provided to customers by bravopolymer.

The largest distributor of polymers in the Middle East