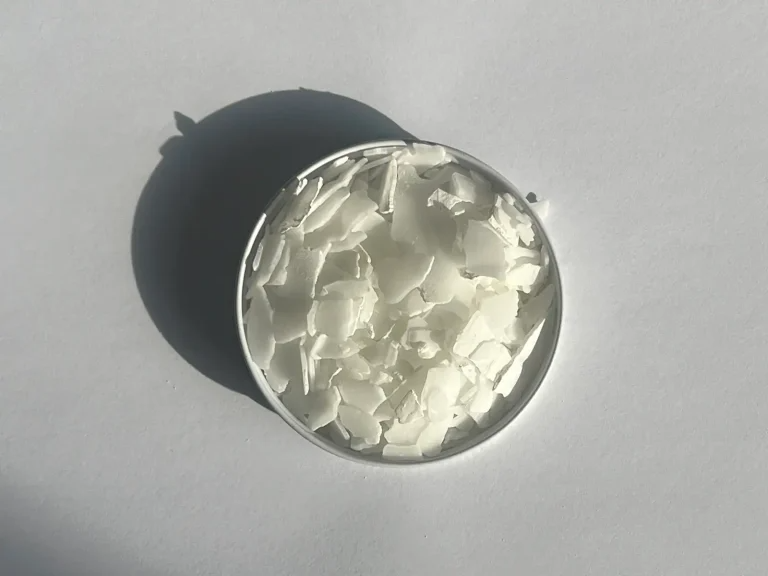

Melamine

Melamine crystal is a white, solid powder widely used in various industries. This product is classified as an organic compound that emits an odor similar to ammonia. This material is also known as “melamine resin”. It is commonly used in the production of plastics, paints, chemical fertilizers, textile manufacturing, key and socket production, aviation industries, MDF sheet production, coatings, decorative industries, and more.

Its butylated form is dissolved in substances like xylene and n-butanol, and after cross-linking with alkyd, epoxy, or acrylic resins, it is used for surface coating. It is an organic compound with the chemical formula C3H6N6. Due to the release of nitrogen gas during combustion or char, this material derivatives have flame-retardant properties.

This organic compound has a molecular weight of 126.12 gr/mol and its melting point is 354 To produce this material from phenolic resin, phenolic resin is first combined with formaldehyde and various catalysts. Then, this mixture is subjected to high temperature and pressure to react together and produce it.

For more information on Melamine prices and ordering methods, you can contact the experts at Petro Nour Mehr Company. The export of this material, worldwide is our expertise.

Melamine Manufacturers in Iran

In the petrochemical industry of Iran, several companies and production units are engaged in the production of Melamine. These companies include:

- Khorasan Petrochemical Company

- Urmia Petrochemical Company

These units are among the largest Melamine producers in Iran and play a significant role in supplying domestic needs and exporting this material to global markets.

Melamine Manufacturers Worldwide

The most important Melamine producers in the world are PerkinElmer Inc, Huaqiang Chemical Group Stock Co., Esprix, nacalai and Merck.

Additionally, other companies may be active in Melamine production or use it as an intermediate substance in manufacturing processes across the globe.

Application of Melamine

This material is used in many industries and applications. Due to its favorable physical and chemical properties, this substance can be used in the following cases:

Drug Production

This material can also be used in drug production. Typically, these products are used in the production of arsenic-containing drugs. One example of these drugs is Melarsoprol, which is used to treat African trypanosomiasis.

Chemical Fertilizer Production

In the past, this product was used to produce various types of chemical fertilizers, and typically, these compounds were used as a non-protein nitrogen source for livestock and their feed.

Color and Paper Production

One of the wide-ranging applications of this material are their use in color production. This chemical product is commonly used in the production of amino colors. Amino colors refer to various types of colors used in the production of bicycle and automotive paints, among others. Additionally, this substance can be used in the paper industry. By employing this product in paper production, it is possible to produce papers with significant transparency and other properties such as waterproofness and wrinkle resistance.

Production of Wooden Panels and Molding Powders

Generally, it should be noted, this chemical product is used in the production of various high-performance products. Among these products, wooden panels can be mentioned. Additionally, this substance is used in the production of various laminates. Different types of coatings are also produced from this substance. On the other hand, it can also be used in the production of molding powders. In general, it should be noted that this substance has many applications in the wood industry.

Typically, melamine crystals are used in this industry for purposes such as wood transparency. Furthermore, this substance can be used in these industries to enhance the beauty and resistance of wooden surfaces, utilizing it as a material resistant to heat and temperature.

Fabric Production

These material are also used in the textile industry. In this industry, this chemical product is used in the production of various fabrics that are waterproof and wrinkle-resistant. Moreover, by employing this product in the production of various fabrics, it is possible to significantly increase their resistance to factors such as washing.

Firefighting Application

This chemical substance is also used in firefighting. Typically, this product is used in this field to produce various flame retardants or to produce materials that have significant heat resistance or can be used as flame retardants.

Application in Concrete Industries

This product can also be incorporated into the process of producing melamine sulfonate and used as a superplasticizer in such conditions. Therefore, this product can be used in the production of high-strength concrete. It should be noted that melamine sulfonate formaldehyde is one of the polymers used as a cement admixture to reduce water content in concrete, while it can increase the fluidity and efficiency of this mixture.

Molding and Wood Glue Production

In the field of molding, this chemical product is used as cellulose fibers in the production of various melamine dinnerware. On the other hand, this substance can also be used to produce wood glue. Wood glue produced using these melamines have properties such as waterproofness. These types of products are also heat resistant, have stable colors, and have very high adhesive properties.

Ink, Plastic, and Leather Production

In general, it can be said those are among the very important and fundamental components of yellow pigments, which are mainly used for ink production and various plastics. Additionally, by using this product in the leather industry, it is possible to produce various types of leathers that are transparent, waterproof, and highly resistant. In the rubber industry, this substance is also used in the production of various rubbers with very high adhesive properties or to increase the adhesion surface of rubbers.

Storage Conditions for Melamine

There are some guidelines for better preservation of its quality:

- It is ideal to keep these materials dry and cool; a temperature of less than 25 degrees Celsius is preferable for storage.

- Keep this material out of direct sunlight and ultraviolet light, since these sources of light may alter its chemical and physical characteristics.

- These substances react with acids and solvents, among other compounds. It is therefore recommended to stay away from direct contact with these kinds of compounds.

- During storage and transportation, ensure that this material is protected from scratches and impacts, as physical damages can lead to changes in its structure and chemical properties.

- Packaging for this grade should be made of suitable material to protect it from environmental changes and reduce the penetration of water and air into the packaging.

- Certain items can need particular storage conditions. Consult the manufacturer’s directions in this situation.

Packaging for Melamine

For packaging and exporting Melamine powders, various methods can be employed depending on environmental conditions, product requirements, and transportation facilitation for export. The following are some typical ways that Melamine powders are packaged and exported:

Packaging in Jambo Bags: This method is common for packaging Melamine powders, where the powders are packed into large bags with varying capacities (usually between 500 to 2000 kilograms). These bags are appropriate for air, sea, and road transportation in addition to protecting the product from contamination and moisture.

Packaging in Small Bags: In this method, this material powders are packed into smaller bags with capacities of approximately 20 to 25 kilograms.

Use of Pallets: Melamine large pallets.

Choosing the right packaging and exporting strategy for this material powders can be accomplished with success if international packaging standards, labeling, and transportation requirements are followed. It’s crucial to think about protecting the product from environmental deterioration, shocks, and humidity while it’s being transported.

Advantages and Disadvantages of Melamine

Melamine crystalline, has various advantages and disadvantages.

Advantages:

- High Melting Point: This material has a relatively high melting point, making it suitable for applications requiring heat resistance.

- Strength and Durability: It is known for its exceptional strength and durability, making it suitable for use in a wide range of products, including kitchenware, tableware, and laminates.

- Chemical Resistance: This material exhibits resistance to many chemicals, acids, and alkalis, enhancing its longevity and usability in diverse environments.

- Low Cost: It is relatively inexpensive compared to alternative materials like porcelain or ceramic, making it a cost-effective option for mass-produced items.

- Ease of Cleaning: Its non-porous surface is easy to clean and maintain, as it resists staining and does not absorb odors.

- Versatility in Design: This material can be molded into various shapes and forms, allowing for versatile design options in terms of color, pattern, and texture.

- Lightweight: It is lightweight compared to materials like ceramic or glass, making it easier to handle and transport.

Disadvantages:

- Not Microwave Safe: This material is not suitable for use in microwave ovens, as it can release harmful chemicals when heated, posing health risks.

- Not Suitable for High-Temperature Applications: While melamine is heat resistant, it may degrade or release toxic fumes when exposed to high temperatures, limiting its use in certain applications.

- Brittleness: Despite its strength, this material can be brittle and prone to chipping or cracking under impact, especially along edges or corners.

- Not Scratch Resistant: It is susceptible to scratching, especially when in contact with sharp utensils or abrasive cleaning tools, which can detract from its appearance over time.

- Limited Repair Options: Unlike some materials, melamine cannot be easily repaired if damaged, often requiring replacement instead.

- Environmental Concerns: It is derived from fossil fuels and synthetic chemicals, raising environmental concerns regarding its production and disposal.

- Potential for Contamination: Low-quality this material products may contain impurities or contaminants, posing health risks if ingested or used for food storage.

Overall, while melamine crystalline offers several advantages in terms of strength, durability, and cost-effectiveness, it also has limitations and considerations regarding its safety, suitability for certain applications, and environmental impact.

Physical and Chemical Properties

These resins are used in many industrial and consumer applications and have important physical and chemical properties. Some of these properties include:

- Mechanical resistance: It has high resistance to pressure, impact, and abrasion, making them suitable for applications such as manufacturing fiberglass composites, laminates, and impact-resistant products.

- Chemical resistance: These resins exhibit high resistance to acids, bases, organic solvents, and even heat, making them a suitable option for applications such as paints, display resins, and chemical-resistant materials.

- Thermal stability: It has high thermal stability, making them suitable for applications such as thermal insulation materials, automotive components, and building materials in high-temperature conditions.

- Hardness and surface finish: Once dried, this material have a smooth and hard surface, resulting in the production of parts with a beautiful and durable appearance.

Types of Melamine grades:

This material has various grades classified based on its physical, chemical, and application properties. Below are some of the types of grades for this substance:

- Phenolic Melamine: These types of this material are produced from the combination of formaldehyde with phenol and melamine. They exhibit high resistance to heat and chemicals and are commonly used in the manufacturing of automotive parts, kitchenware, and building industries.

- Urea Melamine: These melamines are made from the combination of formaldehyde with urea and melamine. They have suitable physical and chemical properties for applications such as impact-resistant products, water-resistant materials, and heat-resistant items.

- Melamine-Formaldehyde: These melamines are produced from the combination of formaldehyde with melamine-formaldehyde. They have high resistance to heat and chemical environments and are commonly used for coating and edge banding in furniture and cabinets.

- Modified Melamines: These melamines have special properties that have been improved through chemical modification during the production process. Examples of this type include high-resistance coating melamines, water-resistant melamines, and heat-resistant melamines.

How to Buy Polyethylene?

- Buy from a reputable and authorized supplier that holds necessary certifications and guarantees quality.

- Compare the prices of these materials in different markets and compare them with the global market price.

- Examine the sales conditions regarding quantity, delivery time, packaging, transportation methods, and payment terms.

- If you intend to import polystyrene from foreign countries, investigate customs and legal regulations and comply with export and import regulations.

- Contact bravopolymer to obtain the most suitable export price based on your conditions.

- After signing the contract, you can place your order.

- Secure and suitable payment methods according to customer preferences are provided by the company.

- Then, the loading stage is completed by selecting and introducing a transport company.

- Necessary documents for customs clearance at the destination city are also provided to customers by bravopolymer.

The largest distributor of polymers in the Middle East