DEG

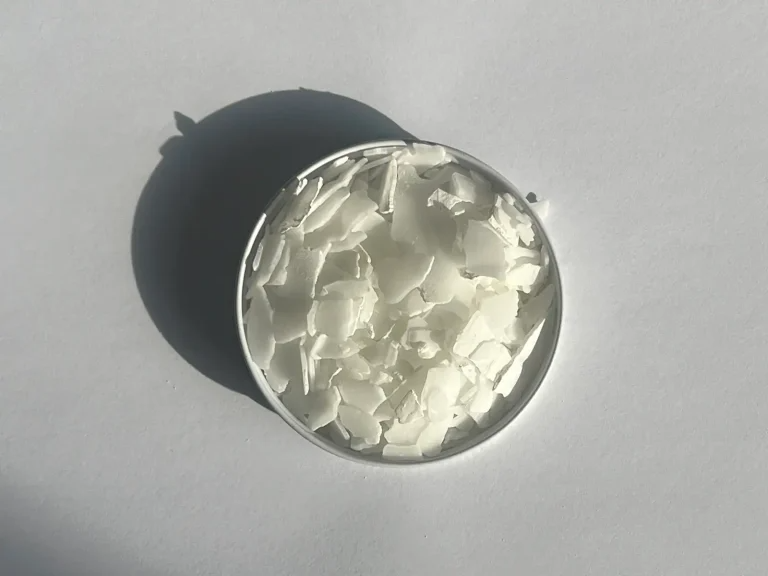

Diethylene glycol (DEG) Diethylene glycol (DEG) is a colorless, odorless, transparent organic compound with the chemical formula C4H10O3, which is soluble in water and many organic compounds. Due to its appropriate moisture absorption capability, it is used in various chemical industries. This compound is widely used as a reactive solvent in the production of plastics and other products. DEG is miscible with water, alcohol, ether, acetone, and ethylene glycol, and is indeed a highly useful solvent. The density of this material is 1.12 gr/cm3 and molecular weight is 106.12 gr/mol. In terms of properties and characteristics, diethylene glycol is very similar to monoethylene glycol, but diethylene glycol has a higher boiling point, viscosity, and density. MEG is the raw material for the production of polyester fibers, PET resins, alkyds, and unsaturated polyesters, whereas diethylene glycol is used in the production of saturated polyester resins, polyurethanes, and plasticizers. For more information on DEG prices and ordering methods, you can contact the experts at Petro Nour Mehr Company.

DEG Manufacturers in Iran

In the petrochemical industry of Iran, several companies and production units are engaged in the production of this material. These companies include:

- Shazand Arak Petrochemical Company

- Marun Petrochemical Company

- Morvarid Petrochemical Company

- Farsa shimi Petrochemical Company

These units are among the largest DEG producers in Iran and play a significant role in supplying domestic needs and exporting this material to global markets.

DEG Manufacturers Worldwide

The most important DEG producers in the world are BASF, Dow Chemical Company, Huntsman Corporation.

Additionally, other companies may be active in DEG production or use it as an intermediate substance in manufacturing processes across the globe.

Applications of DEG

This material finds applications across various industries due to its versatile properties. Some common applications of DEG include:

Polymer Production: This material is used as a raw material in the production of polyesters, polyurethanes, and other polymers. It reacts with various monomers to form polyester resins, which are then used in the manufacture of fibers, films, coatings, and molded parts.

- Solvent and Chemical Intermediate: This material serves as a solvent and chemical intermediate in the synthesis of various organic compounds. It is used in formulations for paints, inks, dyes, adhesives, and coatings. It is also employed as a reaction medium in chemical processes such as esterification and etherification reactions.

- Humectant and Moisture Control: Due to its hygroscopic nature, It is used as a humectant in products such as cosmetics, personal care items, and pharmaceuticals. It helps retain moisture, preventing products from drying out or becoming brittle.

- Coolant and Antifreeze: This Material is used as a component in coolant and antifreeze formulations for automotive engines, HVAC (heating, ventilation, and air conditioning) systems, and industrial equipment. It lowers the freezing point and raises the boiling point of the coolant, protecting engines from overheating and preventing frost damage in cold temperatures.

- Gas Dehydration: This material is utilized in natural gas processing and petrochemical industries for the dehydration of gases. It absorbs water vapor from gas streams, preventing corrosion and freezing in pipelines and equipment.

- Plasticizer: In some applications, It is used as a plasticizer to improve the flexibility, durability, and processing characteristics of polymers and plastics. It enhances the flow properties of polymer melts during processing and improves the mechanical properties of the final products.

- Deicing Agent: This material is added to deicing solutions used for removing ice and snow from roads, airport runways, and sidewalks. It lowers the freezing point of the solution, facilitating the melting of ice and preventing the formation of frost.

These are just a few examples of the diverse applications of diethylene glycol across industries. Its versatility, solubility, and reactivity make it a valuable chemical in numerous manufacturing processes and formulations.

Storage Conditions for DEG

There are some guidelines for better preservation of its quality:

- It is ideal to keep these materials dry and cool; a temperature of less than 25 degrees Celsius is preferable for storage.

- Keep this material out of direct sunlight and ultraviolet light, since these sources of light may alter its chemical and physical characteristics.

- These substances react with acids and solvents, among other compounds. It is therefore recommended to stay away from direct contact with these kinds of compounds.

- During storage and transportation, ensure that this material is protected from scratches and impacts, as physical damages can lead to changes in its structure and chemical properties.

- Packaging for this grade should be made of suitable material to protect it from environmental changes and reduce the penetration of water and air into the packaging.

- Certain items can need particular storage conditions. Consult the manufacturer’s directions in this situation.

Packaging for DEG

This material is typically packaged in containers that are compatible with its chemical properties and safe for transportation and storage. The packaging for DEG should meet certain requirements to ensure its integrity, safety, and regulatory compliance. Here are some common types of packaging used for DEG:

- Drums: It is often packaged in metal drums made of materials such as stainless steel or carbon steel. Drums provide a sturdy and durable packaging option suitable for handling and transportation of bulk quantities of this material. They typically come in various sizes ranging from 200 liters drums to larger capacities.

- Intermediate Bulk Containers (IBCs): IBCs, also known as tote tanks or bulk containers, are large, rigid containers made of materials such as HDPE or composite materials. They offer a cost-effective and space-efficient packaging solution for transporting and storing intermediate quantities of DEG.

- Cans/Bottles: This material may be packaged in smaller cans or bottles made of metal or plastic for retail or consumer applications. These containers are typically used for packaging DEG-based products such as household cleaners, detergents, and personal care products.

Regardless of the type of packaging used, it is important to ensure that the containers are properly sealed, labeled, and compliant with relevant regulatory standards for the safe handling, transportation, and storage of DEG. Additionally, proper safety precautions should be followed when handling and storing this material to prevent exposure and ensure the integrity of the packaging.

Advantages and Disadvantages of DEG

This material has several advantages and disadvantages, especially in industrial applications. Let’s explore them:

Advantages:

- Solubility: This material is highly soluble in water and many organic solvents, making it versatile for use in various formulations and processes.

- Moisture Absorption: It exhibits good moisture absorption properties, which makes it suitable for applications requiring humidity control or as a humectant in cosmetics and personal care products.

- Reactivity: This material serves as a reactive solvent in the production of resins, plastics, and other chemicals, contributing to the formation of desired chemical structures and properties.

- Versatility: It finds applications in a wide range of industries, including textiles, plastics, pharmaceuticals, cosmetics, and automotive, due to its diverse properties and compatibility with other substances.

- Low Volatility: This material has relatively low volatility compared to some other solvents, which can be advantageous in certain processes where controlled evaporation rates are desired.

Disadvantages:

- Toxicity: It is toxic to humans and animals if ingested or absorbed through the skin. Accidental ingestion or exposure can lead to serious health effects, including kidney and liver damage, and even death.

- Regulatory Concerns: Due to its toxicity, It is subject to strict regulations regarding its handling, storage, transportation, and disposal, increasing compliance costs for industries using this compound.

- Odor: While this material is generally odorless in its pure form, it can develop a mild odor when exposed to air for extended periods or when contaminated, which may be undesirable in certain applications.

- Cost: This material may be more expensive than alternative solvents or additives, impacting the overall production costs of products in which it is used.

- Environmental Impact: Improper disposal of this material can lead to environmental contamination, posing risks to ecosystems and human health. Efforts are required to ensure proper handling and disposal to mitigate these risks.

In summary, while this material offers several advantages in terms of its solubility, reactivity, and versatility, its toxicity, regulatory concerns, and potential environmental impact should be carefully considered and managed in industrial applications.

Physical and Chemical Properties:

This material possesses a range of physical and chemical properties that contribute to its utility and behavior in various applications. Here’s an overview:

Physical Properties:

- Appearance: It is typically a clear, colorless, odorless liquid at room temperature.

- Boiling Point: The boiling point of this material is approximately 245 , which is higher than that of water.

- Viscosity: This material is relatively viscous, with a viscosity of around 12 Cp at 20 .

- Solubility: It is highly soluble in water, ethanol, acetone, ether, and many organic solvents.

Chemical Properties:

- Hygroscopicity: This material has a high affinity for water and is hygroscopic, meaning it readily absorbs moisture from the surrounding environment.

- Reactivity: This material can participate in various chemical reactions, including esterification, etherification, and oxidation, making it valuable in the synthesis of polymers, resins, and other organic compounds.

- Acidity/Basicity: This material is a neutral compound with no inherent acidity or basicity under normal conditions.

- Stability: It is stable under normal storage and handling conditions but may decompose when exposed to high temperatures or in the presence of catalysts.

- Toxicity: This material is toxic if ingested or absorbed through the skin, and prolonged exposure can lead to adverse health effects, including kidney and liver damage.

- Flammability: It is not highly flammable, but it may support combustion under certain conditions. It has a flash point above 150

- Degradation: This material may degrade over time, especially when exposed to air, light, or elevated temperatures, which can affect its properties and suitability for certain applications.

Understanding these physical and chemical properties is crucial for the safe handling, storage, and use of diethylene glycol in industrial processes and consumer products.

Types of DEG grades:

It is available in various grades tailored to specific applications and industry requirements. Here are some common types of this material grades:

- Industrial Grade: This is the standard grade of this material used in a wide range of industrial applications, including the production of resins, plastics, textiles, antifreeze, and solvents. Industrial-grade DEG typically meets basic purity and quality specifications but may have higher levels of impurities compared to other grades.

- Technical Grade: Similar to industrial grade, technical-grade DEG is suitable for industrial applications but may have slightly lower purity requirements. It is often used in processes where precise purity is not critical, such as in industrial cleaning solutions or as a solvent in chemical synthesis.

- Reagent Grade: Reagent-grade DEG is of higher purity compared to industrial or technical grades and is typically used in laboratory settings for analytical purposes, chemical reactions, and research applications. It undergoes rigorous quality testing to ensure minimal impurities and high consistency.

- Electronic Grade: This grade of this material is specially purified to meet stringent requirements for use in electronic and semiconductor manufacturing processes. It is free from contaminants that could affect the performance or reliability of electronic components, such as integrated circuits and printed circuit boards.

- Food Grade: It meeting food-grade standards is safe for use in food and beverage applications, where it may be used as a humectant, solvent, or additive. Food-grade this material must comply with regulatory requirements set by food safety authorities, ensuring that it is suitable for consumption without posing health risks.

These are some of the primary types of this material grades available in the market, each catering to specific industry needs and quality standards. Manufacturers may offer additional specialized grades tailored to niche applications or customer requirements.

Comparison between MEG, DEG and TEG:

- Number of Ethylene Glycol Units: The main difference between MEG, DEG, and TEG lies in the number of ethylene glycol units in their chemical structures, with MEG having one, DEG having two, and TEG having three.

- Applications: While all three glycols share some common applications, such as in the production of resins and antifreeze, their specific properties and chemical structures make them better suited for different purposes. MEG is primarily used in polyester production, DEG is a versatile solvent and chemical intermediate, and TEG is mainly employed for dehydration purposes in gas processing.

Understanding these differences is crucial for selecting the appropriate glycol for specific industrial processes and applications.

How to Buy Polyethylene?

- Buy from a reputable and authorized supplier that holds necessary certifications and guarantees quality.

- Compare the prices of these materials in different markets and compare them with the global market price.

- Examine the sales conditions regarding quantity, delivery time, packaging, transportation methods, and payment terms.

- If you intend to import polystyrene from foreign countries, investigate customs and legal regulations and comply with export and import regulations.

- Contact bravopolymer to obtain the most suitable export price based on your conditions.

- After signing the contract, you can place your order.

- Secure and suitable payment methods according to customer preferences are provided by the company.

- Then, the loading stage is completed by selecting and introducing a transport company.

- Necessary documents for customs clearance at the destination city are also provided to customers by bravopolymer.

The largest distributor of polymers in the Middle East