LABSA

Linear Alkyl Benzene Sulfonic Acid (LABSA)

LABSA, or Linear Alkylbenzene Sulfonic Acid, is a chemical compound known as a linear alkyl sulfonic acid. This substance is an important component in the detergent industry and is used in the production of cleaning products such as dishwashing liquid, shampoo, liquid hand soap, and more. It is recognized as a biodegradable and environmentally friendly detergent. Additionally, it acts as a surfactant and, due to its specific properties such as cleansing ability, cooling properties, and low environmental toxicity, it is widely used in the chemical industry. Its density is 1.05 gr/cm3.

Linear alkylbenzene sulfonic acid is commercially produced by sulfonating linear alkyl benzene (LAB) and serves as a preferable alternative to branched alkyl benzene sulfonates such as ABS.

The chemical formula of Linear Alkyl Benzene Sulfonic Acid (LABSA) is typically CnH2n+1SO3H, where n represents the number of carbon atoms in the linear alkyl chain and n varies between 10 to 16.

For more accurate information regarding prices or purchasing the product, it is better to contact the sales department of Petro Nour Mehr Company.

LABSA Manufacturers in Iran

Some popular factories are producers of this chemical material in Iran.

LABSA Manufacturers Worldwide

Manufacturers of this material can be found worldwide, including countries such as the United States, Canada, Mexico, and Brazil. These countries are known for their rapidly growing chemical industries, and it is possible that companies and factories within them are engaged in the production of it. For example, in the United States, renowned chemical companies like Dow Chemical Company are involved in this material production. Similarly, in Canada, companies like Nova Chemicals and others may be active in this field. In Mexico and Brazil, there are also large chemical companies that may be engaged in this material production. These manufacturers typically operate in supplying their products to both domestic and international markets.

Applications of LABSA

This material finds a wide range of applications across various industries due to its surfactant properties and versatile nature. Some of the common applications of this material include:

Detergents : It is extensively used in the production of household and industrial detergents, including laundry detergents, dishwashing liquids, and surface cleaners. Its excellent foaming and cleaning properties make it an essential ingredient in detergent formulations.

- Personal Care Products : This material is employed in the formulation of personal care products such as shampoos, hand wash liquids, body washes, and bath gels. It serves as a primary surfactant, contributing to the cleansing and foaming properties of these products.

Industrial Cleaning : This material is utilized in various industrial cleaning applications, including vehicle cleaning, degreasing, and equipment maintenance. Its strong cleaning power and ability to emulsify oils and greases make it suitable for industrial cleaning purposes.

Textile Industry : It is employed in the textile industry for fabric pretreatment, dyeing, and finishing processes. It helps to remove impurities from textiles, enhance dye absorption, and improve the overall quality of finished fabrics.

Emulsion Polymerization : This material is used as an emulsifier in the production of synthetic latex polymers through emulsion polymerization processes. It aids in the stabilization of polymer particles in water and facilitates the formation of stable emulsions.

Oilfield Chemicals : It is utilized in the oil and gas industry for various applications, including drilling fluids, oil recovery processes, and well stimulation treatments. It helps to improve the performance of oilfield chemicals and enhance their effectiveness in oilfield operations.

Agrochemicals : This material serves as a key ingredient in the formulation of agricultural chemicals such as herbicides, pesticides, and insecticides. It assists in the dispersion and delivery of active ingredients in agricultural formulations, improving their efficacy.

- Adhesives and Sealants : It is employed in the manufacturing of adhesives, sealants, and caulks, where it acts as a surfactant and emulsifying agent. It helps to stabilize adhesive formulations and improve their bonding properties.

Overall, LABSA plays a vital role in various industrial processes and products, contributing to their performance, effectiveness, and quality.

Storage Conditions for LABSA

Storage conditions for Linear Alkylbenzene Sulfonic Acid (LAS) must be carefully observed to prevent its degradation and chemical changes. The proper storage conditions for LAS can be summarized as follows:

Temperature : LAS should be stored at temperatures below 30 degrees Celsius. Higher temperatures may lead to degradation and chemical changes in LAS.

Light : LAS storage environment should be shielded from direct sunlight. Direct sunlight can cause degradation and decrease the quality of LAS.

Linear alkylbenzene sulfonic acid should be stored in a cool and dry environment. Moist environments may lead to chemical changes and moisture formation in this chemical substance.

This chemical substance should be stored in appropriate packaging to protect it from contact with air and moisture. The use of non-permeable bottles and containers can be beneficial in this regard.

This material should be protected from substances that may cause chemical reactions. Therefore, contact of this chemical substance with oxidizing, alkaline, or acidic substances should be prevented.

By observing these storage conditions, undesirable changes and degradation of LAS can be prevented, and its quality can be maintained. Given that heavy alkyl benzene is a hazardous substance, safety information and relevant guidelines should always be followed, and safety equipment such as masks and protective clothing should be used.

Packaging for LABSA

This material is typically packaged in various containers suitable for its storage, transportation, and use in different industries. The packaging options for this material may include:

- Drums: It is commonly packaged in standard-sized drums made of materials such as carbon steel, stainless steel, or high-density polyethylene (HDPE). These drums typically have a capacity ranging from 50 liters to 250 liters and are suitable for bulk storage and transportation.

- Intermediate Bulk Containers (IBCs): This material may also be stored and transported in IBCs, which are large containers with a capacity of 1000 liters or more. IBCs are constructed from materials like high-density polyethylene (HDPE) or composite materials and are equipped with a pallet base for easy handling.

- Bulk Tankers: For large-scale transportation, it is often transported in bulk tanker trucks or railcars. These specialized vehicles are designed to safely transport large quantities of liquid chemicals and may have built-in heating or cooling systems to maintain the desired temperature during transit.

- ISO Tanks: It can also be shipped internationally in ISO tanks, which are standardized containers suitable for intermodal transportation via road, rail, or sea. ISO tanks have a capacity similar to tanker trucks and provide a secure and efficient means of transporting this material in liquid form.

Regardless of the type of packaging used, it is essential to ensure that containers are properly sealed, labeled, and handled in accordance with safety regulations and guidelines to prevent spills, contamination, or other hazards during storage and transportation.

Advantages and Disadvantages of LABSA

Below are the advantages and disadvantages of this material :

Advantages

- This material exhibits high activity, making it useful in producing raw materials for pharmaceuticals, detergents, dyes, and resins.

- These compounds have good solubility in water, which is crucial for various chemical processes.

- This material chemicals generally exhibit good chemical stability, making them suitable as catalysts or raw materials in complex syntheses.

- The linear structures of these compounds can provide high strength, making them useful in various industries.

Disadvantages

- Some linear alkylbenzene sulfonic acids may be toxic and harmful to the environment and humans. Therefore, it’s crucial to observe safety and environmental precautions in industries that use these compounds.

- Some of these compounds may have high density, leading to challenges in production processes and transportation.

- This material chemicals are sensitive to environmental conditions such as temperature and pressure, which should be considered in their production and usage processes.

- Improper management and disposal of this material may lead to environmental pollution, emphasizing the need to adhere to environmental standards.

In general, linear alkylbenzene sulfonic acids have their own set of advantages and disadvantages, and their usage in various industries requires careful evaluation and cautious handling.

Physical and Chemical Properties of LABSA

This material exhibits a range of physical and chemical properties that make it suitable for various industrial applications. Here are some of its key properties:

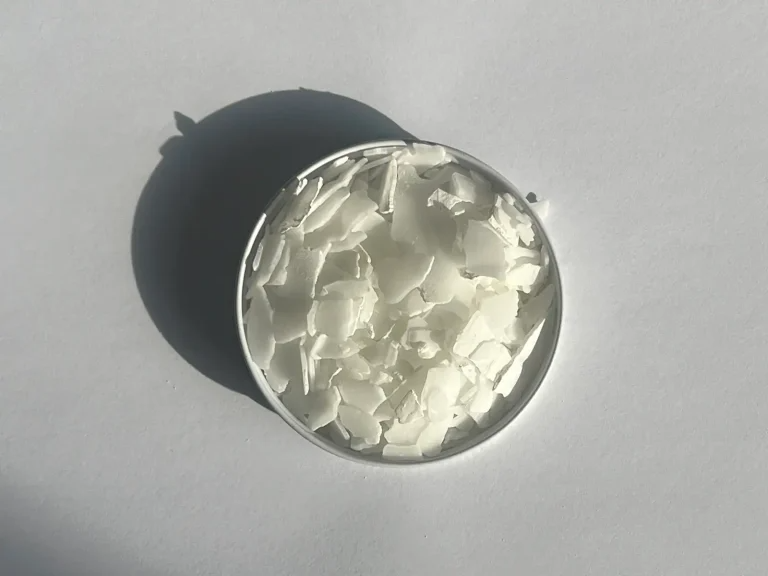

Appearance : It is typically a viscous, brownish-yellow liquid at room temperature. It may appear as a clear to slightly cloudy solution, depending on its purity and concentration.

Molecular Weight : The molecular weight of this material varies depending on the length of the alkyl chain. For example, for linear alkyl chains ranging from C10 to C14, the molecular weight typically falls between 320 to 360 g/mol.

Solubility : It is soluble in water and forms clear to slightly cloudy solutions. Its solubility in water increases with higher temperatures and agitation. This material is also soluble in polar organic solvents such as ethanol and methanol.

Acidic Nature : It is a strong organic acid due to the presence of the sulfonic acid group (-SO3H). It readily donates protons in aqueous solutions, leading to its acidic properties. The pH of a typical this material solution range from 1 to 3, depending on its concentration.

Density : The density of this material is approximately 1.05 g/cm³ at room temperature. However, this value may vary slightly depending on the purity and concentration of the this material solution.

Hygroscopicity : This material has hygroscopic properties, meaning it can absorb moisture from the surrounding environment. This can lead to changes in viscosity and concentration over time, especially in humid conditions.

Biodegradability : This material is considered biodegradable under aerobic conditions, meaning it can be broken down by microorganisms in the presence of oxygen. However, the rate of biodegradation may vary depending on factors such as concentration, temperature, and microbial activity.

Overall, these physical and chemical properties make this material a versatile compound widely used in detergent formulations, industrial cleaners, personal care products, and various other applications in the chemical industry.

Comparison of the family of alkylbenzenes with LABSA

This material are two main categories of organic compounds with wide-ranging applications in the field of chemistry and related industries. Alkylbenzenes consist of a benzene ring and an alkyl chain attached to the benzene nucleus. These compounds typically exist as liquids or solids at room temperature and standard conditions and are used as solvents in the extraction and processing of chemical materials.

On the other hand, this material compounds feature a sulfonic acid group attached to an alkyl chain. These compounds are solid at room temperature and under standard conditions and serve as raw materials in the production of pharmaceuticals, dyes, protective materials, and detergents. Additionally, linear alkylbenzene sulfonic acids are well-known for their involvement in sulfonation reactions, where the sulfonic acid group is attached to the benzene nucleus.

In general, both categories of alkylbenzenes and LABSA differ structurally and functionally and hold significant importance in the chemical and chemical materials industries.

Types of LABSA grades

This material is available in different grades to meet various application requirements and industry standards. Some common types of this material grades include:

Normal LABSA (NLABSA) : This is the standard grade of this material, produced by sulfonating linear alkylbenzene (LAB) with sulfuric acid. It typically contains a mixture of alkyl chains ranging from C10 to C14. NLABSA is widely used in detergent formulations, personal care products, industrial cleaners, and other applications.

Heavy LABSA (HLABSA) : HLABSA is a higher molecular weight variant of LABSA, containing longer alkyl chains, typically ranging from C14 to C18. It offers enhanced cleaning power and foaming properties compared to NLABSA. HLABSA is commonly used in heavy-duty detergents, industrial cleaners, and specialty applications where greater cleaning performance is required.

Light LABSA (LLABSA) : LLABSA is a lighter version of LABSA, containing shorter alkyl chains, usually ranging from C10 to C12. It exhibits excellent solubility and foaming characteristics, making it suitable for applications where rapid dispersion and penetration are desired, such as liquid detergents and personal care products.

Neutralized LABSA : In this grade, this material is partially or fully neutralized with alkalis such as sodium hydroxide or potassium hydroxide to form alkylbenzene sulfonate salts. Neutralized LABSA offers improved handling, stability, and compatibility with other ingredients in formulations. It is commonly used in solid detergent bars, powdered detergents, and dishwashing formulations.

Specialty Grades : Manufacturers may offer specialty this material grades tailored to specific applications or customer requirements. These specialty grades may have customized properties such as higher purity, lower color, reduced odor, or enhanced biodegradability to meet the needs of niche markets or environmentally sensitive applications.

These are some of the common types of this material grades available in the market, each designed to cater to different industrial sectors and application scenarios.

How to Buy Polyethylene?

- Buy from a reputable and authorized supplier that holds necessary certifications and guarantees quality.

- Compare the prices of these materials in different markets and compare them with the global market price.

- Examine the sales conditions regarding quantity, delivery time, packaging, transportation methods, and payment terms.

- If you intend to import polystyrene from foreign countries, investigate customs and legal regulations and comply with export and import regulations.

- Contact bravopolymer to obtain the most suitable export price based on your conditions.

- After signing the contract, you can place your order.

- Secure and suitable payment methods according to customer preferences are provided by the company.

- Then, the loading stage is completed by selecting and introducing a transport company.

- Necessary documents for customs clearance at the destination city are also provided to customers by bravopolymer.

The largest distributor of polymers in the Middle East