MDI

Methylene diphenyl diisocyanate (MDI)

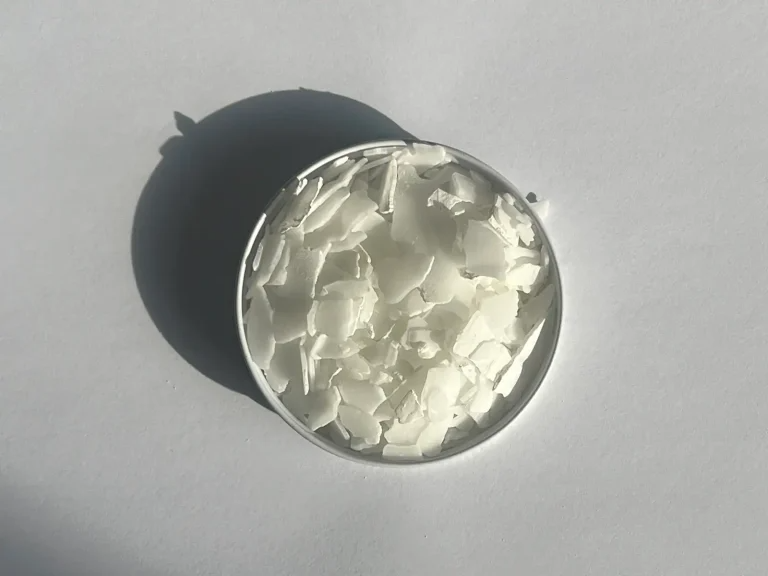

Methylene diphenyl diisocyanate (MDI), abbreviated as MDI, is a chemical compound formed by linking two molecules of phenyl diisocyanate together. Its chemical formula is C15H10N2O2, with a molecular weight of 250 gr/mol and a density of 1.23 gr/cm3. This substance is used as a fundamental element in the production of polyurethanes, which are themselves polymers with various physical and chemical properties used in diverse industries such as automotive, construction, coatings, and consumer products.

The reaction of MDI with bisphenol or alcohols leads to the production of polyurethane, which is used in various industries for purposes such as insulation, and soft and hard foams.

Diphenyl diisocyanate is the most important diisocyanate produced globally and accounted for approximately 61.3% of the global market in 2000. Global production of this polymer substance amounted to over 7.5 million tons per year by 2017.

For more information on MDI prices and ordering methods, you can contact the experts at Petro Nour Mehr Company.

MDI Manufacturers in Iran

Karun Petrochemical and other domestic factories are producers of this polymer material in Iran.

These units are among the largest MDI producers in Iran and play a significant role in supplying domestic needs and exporting this material to global markets.

MDI Manufacturers Worldwide

This material is a chemical compound used in the production of various polyurethane foams and coating materials. Some major manufacturers of MDI include Huntsman Corporation, Covestro, and The Dow Chemical Company. These companies are among the most reputable and largest producers of MDI worldwide, and their products are used in various industries such as construction, automotive, and coatings.

Additionally, other companies may be active in this material production or use it as an intermediate substance in manufacturing processes across the globe.

Applications of MDI

This material finds a wide range of applications across various industries due to its versatile properties. Some common applications of MDI include:

- Polyurethane Foam Production: It is primarily used in the production of polyurethane foams, including rigid foams, flexible foams, and spray foams. These foams are utilized in insulation materials for buildings, appliances, refrigerators, and freezers, as well as in automotive seating, cushions, mattresses, and upholstery.

- Adhesives and Sealants: MDI-based polyurethane adhesives and sealants offer strong bonding capabilities and excellent durability. They are used in construction, woodworking, automotive assembly, packaging, and other industries for bonding various substrates, including wood, metal, plastic, and composite materials.

- Coatings and Paints: This material can be incorporated into polyurethane-based coatings and paints to enhance their durability, weather resistance, and adhesion properties. These coatings are used in architectural coatings, automotive refinishing, industrial coatings, flooring, and corrosion protection applications.

- Composite Materials: It is used as a binder or matrix resin in the production of composite materials, such as fiberglass-reinforced plastics (FRP), carbon fiber composites, and composite panels. These materials are used in aerospace, marine, wind energy, sports equipment, and automotive applications.

- Footwear and Textiles: MDI-based polyurethane elastomers are used in the manufacturing of footwear, sportswear, and textiles due to their elasticity, abrasion resistance, and comfort. MDI-based coatings are also used to enhance the water repellency and durability of fabrics and textiles.

- Automotive Parts and Components: MDI-based polyurethane materials are used in automotive interiors, including instrument panels, door panels, headliners, and armrests, as well as in exterior components such as bumpers, spoilers, and body panels, due to their lightweight, impact resistance, and design flexibility.

- Insulation Panels and Boards: MDI-based polyurethane foam boards and panels are used for thermal insulation in construction applications, such as walls, roofs, and refrigerated storage facilities. These materials offer high thermal resistance, moisture resistance, and energy efficiency.

- Packaging and Cushioning: MDI-based polyurethane foams are used in packaging materials, including protective packaging inserts, cushioning materials, and molded foam products, to provide shock absorption, vibration damping, and product protection during shipping and handling.

These are just a few examples of the diverse applications of MDI across industries. Its versatility, durability, and performance make it a valuable component in various products and materials.

Storage Conditions for MDI

The storage conditions of this material are crucial to maintain its stability and prevent degradation. Here are the recommended storage conditions for it:

- Temperature: This material should be stored at temperatures below 25 Higher temperatures can accelerate chemical reactions and lead to degradation of the product.

- Humidity: It should be stored in a dry environment to prevent moisture absorption. High humidity levels can cause hydrolysis of this material, leading to a decrease in product quality.

- Ventilation: Adequate ventilation should be provided in the storage area to prevent the buildup of vapors. It can release volatile organic compounds (VOCs), which may pose health risks if inhaled in high concentrations.

- Light exposure: This material containers should be stored away from direct sunlight and sources of UV radiation. Prolonged exposure to light can promote chemical reactions and degradation of it.

- Container integrity: It should be stored in tightly sealed containers to prevent contamination and exposure to air. Partially filled containers should be tightly closed to minimize air exposure and moisture ingress.

By following these storage conditions, the quality and stability of this material can be preserved, ensuring its suitability for various applications in polymer engineering.

Packaging for MDI

This material is typically packed and stored in containers designed to ensure its integrity and prevent contamination. Common packaging options for MDI include:

- Drums: This material is often packaged in steel or plastic drums with capacities ranging from 200 liters to 250 liters. These drums provide a secure and sealed environment for storing this material and are suitable for both transportation and long-term storage.

- Intermediate Bulk Containers (IBCs): IBCs are large, reusable containers with capacities typically ranging from 500 liters to 1,000 liters. They are made of durable materials such as plastic or metal and are designed for safe handling and transportation of this material in bulk quantities.

- Bulk Tankers: For large-scale industrial applications, This material may be transported and stored in bulk tanker trucks or railcars. These tankers are specifically designed to handle liquid MDI and are equipped with safety features to prevent leaks or spills during transportation.

- Customized Packaging: In some cases, This material may be packaged in customized containers or packaging formats tailored to specific customer requirements or application needs. This may include bag-in-box packaging, flexi tanks, or other specialized containers.

Regardless of the packaging format used, proper labeling and handling instructions should be provided to ensure safe storage, transportation, and usage of this material. Additionally, packaging materials should be compatible with this material to prevent chemical reactions or degradation that could compromise product quality.

Advantages and Disadvantages of MDI

This material offers several advantages and disadvantages, as outlined below:

Advantages:

- Versatility: It is widely used in the production of polyurethane foams, coatings, adhesives, and elastomers, making it a versatile chemical compound.

- Strength and Durability: Polyurethane products made with this material exhibit excellent strength, durability, and resistance to wear and tear, making them suitable for various applications in construction, automotive, and other industries.

- Thermal Insulation: MDI-based polyurethane foams provide effective thermal insulation, helping to improve energy efficiency in buildings and vehicles.

- Chemical Resistance: Polyurethane products formulated with this material are often resistant to many chemicals, oils, and solvents, enhancing their suitability for use in harsh environments.

- Adhesion: MDI-based adhesives offer strong bonding properties, making them suitable for joining various materials together.

Disadvantages:

- Toxicity: This material is classified as a hazardous substance due to its potential to cause respiratory irritation, sensitization, and other health effects upon inhalation or skin contact. Proper safety measures must be followed during handling and processing.

- Environmental Impact: This material production and disposal can pose environmental risks, including air and water pollution. Efforts are needed to minimize emissions and ensure proper waste management.

- Cost: This material can be relatively expensive compared to other polyurethane precursors, which may impact the overall cost of products manufactured using MDI-based formulations.

- Handling Challenges: It is highly reactive and must be handled with care to prevent unwanted reactions or polymerization. Specialized equipment and safety protocols are necessary for safe handling and processing.

- Regulatory Compliance: This material is subject to strict regulations and guidelines due to its hazardous nature. Manufacturers must comply with safety standards and regulatory requirements to ensure worker safety and environmental protection.

Overall, while this material offers various advantages in terms of performance and versatility, its use requires careful consideration of safety, environmental, and regulatory factors.

Physical and Chemical Properties of MDI:

This material is a chemical compound with both physical and chemical properties that make it suitable for various industrial applications, particularly in the production of polyurethane foams, coatings, adhesives, and elastomers. Here are some of its key physical and chemical properties:

Physical Properties:

- Appearance: It is typically a colorless to pale yellow liquid at room temperature, although it can also be found in solid or powdered form.

- Odor: This material may have a distinct, pungent odor, which can vary depending on its concentration and purity.

- Melting Point: The melting point of this material can range from around 38 to 45 , depending on its specific chemical composition and form.

- Boiling Point: This material generally has a relatively high boiling point, typically above 250 which makes it stable at elevated temperatures.

- Density: The density of this material is approximately 1.2 to 1.3 g/cm³, depending on its molecular structure and form.

Chemical Properties:

- Reactivity: It is highly reactive due to the presence of two isocyanate (-NCO) functional groups in its molecule. These groups readily react with compounds containing active hydrogen atoms, such as polyols, to form polyurethane polymers.

- Polymerization: This material undergoes polymerization reactions when mixed with polyols, leading to the formation of polyurethane chains. The reaction between this material and polyols is exothermic and occurs rapidly under appropriate conditions.

- Crosslinking: MDI-based polyurethane systems can undergo crosslinking reactions, which contribute to the development of the final product’s mechanical properties, such as strength, elasticity, and dimensional stability.

- Solubility: It is typically insoluble in water but can dissolve in many organic solvents, including acetone, methylene chloride, and aromatic hydrocarbons.

- Stability: This material exhibits good thermal stability under normal storage and processing conditions, but it may undergo decomposition at high temperatures or in the presence of catalysts or impurities.

Overall, the physical and chemical properties of this material make it a valuable building block for the synthesis of polyurethane materials with diverse applications across various industries. However, its reactivity and potential hazards require careful handling and processing to ensure safety and product quality.

Types of MDI grades:

This material is available in several different grades, each tailored to specific applications and processing requirements. Some common types of this material grades include:

- Pure MDI (PMDI): Pure MDI is the most basic form of MDI, consisting predominantly of 4,4′-methylenediphenyl diisocyanate. It is typically used in applications where high purity and minimal impurities are required, such as in the production of high-performance polyurethane elastomers, coatings, and adhesives.

- Polymeric MDI (PMDI): Polymeric MDI contains a mixture of MDI isomers, oligomers, and higher molecular weight polymers. It is often used in the production of rigid polyurethane foams for insulation in construction, refrigeration, and appliances. PMDI grades may vary in functionality, viscosity, and reactivity to suit different foam formulations and processing conditions.

- Modified MDI: Modified MDI grades are chemically modified versions of MDI designed to enhance specific properties or processing characteristics. These modifications may include blocking one or both isocyanate groups, introducing functional groups, or altering the molecular structure to improve compatibility with other components in polyurethane formulations.

- High-purity MDI: High-purity MDI grades are refined to remove impurities and contaminants, making them suitable for applications requiring stringent quality control, such as in the production of medical devices, food contact materials, and electronics.

- Blended MDI: Blended MDI grades are mixtures of MDI with other isocyanate compounds or polyols to achieve specific performance characteristics or cost savings. Blends may be tailored to optimize properties such as reactivity, cure profile, mechanical strength, or compatibility with other formulation components.

- Low free MDI: Low free MDI grades are formulated to minimize the concentration of unreacted or free isocyanate groups, reducing the risk of skin sensitization and emissions of volatile organic compounds (VOCs) during processing and curing.

These are just a few examples of the types of MDI grades available in the market. The choice of grade depends on factors such as the desired properties of the final product, processing requirements, regulatory considerations, and cost considerations.

How to Buy Polyethylene?

- Buy from a reputable and authorized supplier that holds necessary certifications and guarantees quality.

- Compare the prices of these materials in different markets and compare them with the global market price.

- Examine the sales conditions regarding quantity, delivery time, packaging, transportation methods, and payment terms.

- If you intend to import polystyrene from foreign countries, investigate customs and legal regulations and comply with export and import regulations.

- Contact bravopolymer to obtain the most suitable export price based on your conditions.

- After signing the contract, you can place your order.

- Secure and suitable payment methods according to customer preferences are provided by the company.

- Then, the loading stage is completed by selecting and introducing a transport company.

- Necessary documents for customs clearance at the destination city are also provided to customers by bravopolymer.

The largest distributor of polymers in the Middle East