VAM

Vinyl acetate monomer (VAM)

Vinyl Acetate Monomer (VAM) is an essential chemical compound widely used as a key component in the production of various polymers. It is derived from ethylene and acetic acid and is highly valued for its versatility in industries such as adhesives, paints, coatings, packaging films, and textiles. VAM is also crucial in the production of PVC, which is used in everyday products like hygiene items, flooring, and building materials.

Petro Nour Mehr Company has successfully exported this substance to multiple countries at competitive prices, securing a significant share in the global market.

If you are looking for the best VAM prices or detailed information about Vinyl Acetate Monomer pricing and purchasing options, feel free to contact the sales department of Petro Nour Mehr Company

VAM Manufacturers in Iran

In the petrochemical industry of Iran, several companies and production units are engaged in the production of VAM. These companies include:

- Shazand Arak Petrochemical Company

- Bandar Imam Petrochemical Company

These units are among the largest VAM producers in Iran and play a significant role in supplying domestic needs and exporting this material to global markets.

Applications of DEA

- Paints and Resins: When it comes to paints and resins, this grade helps to improve the quality of colors and coatings because of its remarkable film-forming capacity and compatibility with a wide range of pigments and additives. As a result, coatings with a high resistance to degradation are produced, enhancing the life of surfaces.

100vw, 768px” data-lazy-src=”https://petronourmehr.com/wp-content/uploads/2024/08/paint1-768×433.webp” /></div></div><div class=)

- Textile Industry: In the textile industry, polymers containing this grade are utilized to improve properties such as water repellency and softness. These copolymers enhance the durability, softness, and wrinkle resistance of fabrics. Their mechanism of action lies in their ability to adhere to fibers and create a protective layer, thereby improving fabric performance.

- Paper Coatings: In the paper industry, this material is used to produce paper coatings. The use of coatings containing VAM enhances print quality and brings about clearer and livelier images. Additionally, these additional layers also reinforce the paper’s resistance to tearing and lengthen its shelf life.

- Specialty Polymers Production: VAM Chemical serves as a key building block in the production of specialty polymers used in industries such as automotive, household appliances, and electronics. These polymers are known for their unique characteristics, including high heat resistance, strength, and excellent flexibility.

- Adhesives Industry: This Material is a primary material for the production of various industrial and household adhesives. Adhesives made from this grade are widely used in packaging, manufacturing, and repair due to their strong bonding properties.

- Waterproof Coatings: This grade is used in the creation of waterproof coatings for various surfaces, including fabrics, flooring, and construction materials. These coatings help enhance resistance to moisture and humid environments.

- Pharmaceutical Industry: In the pharmaceutical sector, this grade is used in the production of controlled-release medication systems and drug delivery systems. It acts as a polymer in formulations that require gradual release of drugs over time.

- Agricultural Industry: this material is also used in the production of certain coatings and additives for agriculture, helping to improve soil performance, control pests, and increase crop yields.

As a widely used substance, this material is supplied by various VAM producers around the world. Its VAM price can vary depending on the region and market conditions. VAM chemical has become an essential component in numerous manufacturing processes and formulations. Its versatility, solubility, and reactivity make it a highly valuable chemical in diverse industrial applications.

Storage Conditions for VAM

This grade should be stored under proper conditions to maintain its quality and stability. These are the recommended storage conditions for this material to ensure optimal performance:

- Temperature: This material should be stored in a cool, dry, and well-ventilated area. The ideal storage temperature is below 25°C to prevent polymerization and degradation, ensuring its effectiveness in industrial applications.

- Avoid High Temperatures: High temperatures can accelerate unwanted chemical reactions and lead to the polymerization of vinyl acetate monomer. It is critical to keep the storage temperature below 40 °C to maintain product stability.

- Protection from Sunlight: Containers of this grade must be kept away from direct sunlight and heat sources. Exposure to ultraviolet (UV) radiation can degrade the product and affect its purity.

- Container Material: Use appropriate storage containers such as stainless steel, aluminum, and HDPE to prevent contamination and unwanted reactions. Avoid materials that may react with this material or compromise its quality.

- Seal Containers Properly: Ensure that containers are tightly sealed to prevent exposure to moisture and air, which could lead to the formation of peroxides or polymerization. Proper sealing is essential to preserving the integrity of VAM chemicals.

- Labeling: Clearly label containers with safety information, handling guidelines, and product details to ensure safe usage and prevent misidentification.

- Compatibility: Store VAM away from incompatible substances such as strong oxidizing agents, acids, alkalis, and flammable materials to prevent hazardous reactions. It is also important to keep it away from food and beverages.

- Handling Precautions: When handling vinyl acetate monomer, use proper personal protective equipment (PPE) such as gloves, safety goggles, and protective clothing to prevent direct contact with skin or inhalation of vapors.

By following these storage conditions, this material can be preserved effectively, maintaining its quality for industrial use. If you are looking for the best VAM price or need more details about vinyl acetate monomer price, trusted VAM producers can provide up-to-date information on availability and pricing.

Packaging for VAM

Vinyl Acetate Monomer, commonly known as VAM chemical, is packaged and stored in various types of containers suitable for its transportation and industrial applications. Due to its volatile and flammable nature, proper packaging is essential to ensure safe handling. The packaging for this material typically includes:

- Drums: Vinyl Acetate Monomer is often stored in carbon steel, stainless steel, or high-density polyethylene (HDPE) drums with standard capacities ranging from 200 liters to 250 liters. These drums provide a secure and manageable option for transporting and storing moderate quantities of VAM.

- Intermediate Bulk Containers (IBCs): This grade can also be stored and transported in IBCs with a capacity of around 1000 liters. These containers, typically made of high-density polyethylene (HDPE) or composite materials, provide durability and ease of handling while minimizing contamination risks.

- Tanker Trucks: For large-scale industrial use, this material is often transported in tanker trucks specifically designed for liquid chemicals. These trucks are equipped with vapor recovery systems and pressure control to maintain safety during transit.

- ISO Tanks: Vinyl Acetate Monomer is frequently shipped in ISO tanks, which are standardized intermodal containers used for bulk liquid transportation. These tanks offer a secure and efficient solution for global VAM transport via road, rail, or sea.

Regardless of the packaging type, it is crucial to ensure proper sealing, labeling, and storage to prevent polymerization, contamination, or hazardous reactions. VAM producers offer various packaging options, and VAM prices may vary based on packaging type and transportation method. For updated vinyl acetate monomer price and bulk supply options, consulting reliable VAM producers is recommended.

Producing Products Using VAM at Manufacturers

In the United States, VAM producers such as Celanese and Lyondell-Basell leverage Vinyl Acetate Monomer (VAM) as a crucial raw material in their production processes. Celanese specializes in manufacturing high-performance emulsions and adhesives used in industries such as construction, textiles, and coatings. Meanwhile, LyondellBasell, a global leader in VAM chemical utilization, supplies key materials for producing polyvinyl acetate (PVA) and ethylene-vinyl acetate (EVA) copolymers, which are widely used in adhesives, films, and industrial coatings. The competitive VAM price offered by these producers highlights their efficiency and commitment to sustainable production, meeting both domestic and global market demands.

VAM Characteristics

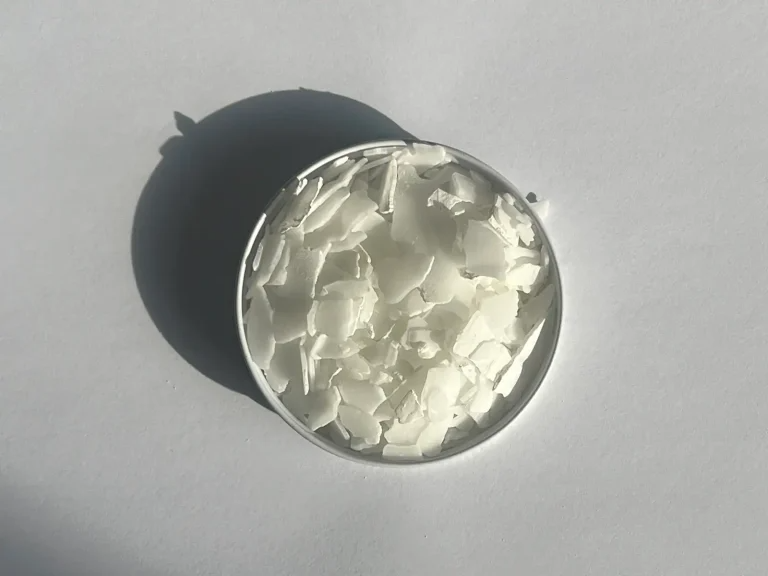

This material is a colorless, flammable liquid with a strong, sweet odor. It is highly soluble in organic solvents like alcohol, acetone, and ether but only slightly soluble in water. VAM has a low boiling point of around 72 °C, which makes it volatile and reactive in certain conditions. Its chemical formula is C₄H₆O₂.

This grade is an organic compound with an ester functional group, which provides it with distinctive chemical properties. The molecule consists of a vinyl group (C=CH₂) and an acetyl group (COO), allowing it to undergo polymerization when exposed to heat or light. With a molecular weight of 86.09 g/mol, this material is an important raw material used in the production of various polymers, including polyvinyl acetate (PVA) and ethylene-vinyl acetate (EVA), which are widely used in adhesives, coatings, and films. VAM’s chemical structure and properties give it versatile applications across industries such as adhesives, textiles, packaging, and automotive.

Advantages and Disadvantages of VAM

VAM, also referred to as Vinyl Acetate Monomer, has several advantages and disadvantages:

Advantages

- Versatility: This material is a highly versatile chemical used across various industries such as adhesives, coatings, textiles, automotive, and packaging. Its ability to polymerize allows for the creation of polymers with different properties.

- Adhesive Properties: This compound plays a crucial role in the production of adhesives and sealants. When polymerized, it forms polyvinyl acetate (PVA), which is widely used to create strong and durable adhesives in various industries.

- Chemical Intermediate: Vinyl Acetate is an essential chemical intermediate used in producing various polymers, including ethylene-vinyl acetate (EVA). These polymers are widely applied in packaging, footwear, and solar panels.

- Film Formation: It is important in the production of films, especially in the packaging industry. Its ability to form smooth, flexible films makes it valuable for packaging materials that require both durability and clarity.

- Low Volatility: The compound has relatively low volatility, making it suitable for formulations that require low vapor pressure, such as adhesives and coatings.

- Biodegradability: Polyvinyl acetate and other polymers derived from this substance can be biodegradable under certain conditions, which helps reduce the environmental impact when properly managed.

Disadvantages

- Toxicity: While generally safe for industrial applications, it can be harmful if inhaled or ingested in large quantities. Proper safety measures and protective equipment are essential to prevent exposure.

- Flammability: The compound is flammable, posing a fire risk if exposed to open flames, sparks, or high temperatures. Strict storage and handling protocols are necessary to ensure safety.

- Corrosiveness: This material can be corrosive to certain metals, which means compatibility checks for equipment, containers, and pipelines used in its storage and handling are required.

- Environmental Impact: Improper disposal can lead to environmental contamination, which can affect ecosystems. Proper waste management and disposal practices are crucial to mitigating environmental harm.

In summary, while this chemical offers numerous benefits for industrial applications, it is essential to handle, store, and dispose of it properly to mitigate risks. Additionally, its price may vary based on market conditions, so businesses should stay updated on this material price and consult reliable VAM producers for competitive pricing.

Physical and Chemical Properties of VAM

Vinyl Acetate Monomer, commonly referred to as VAM, exhibits several physical and chemical properties that make it indispensable in various industrial applications:

Physical Properties

- Appearance: This compound is a colorless, flammable liquid with a distinct sweet odor.

- Melting Point: It has a melting point of approximately -93 °C.

- Boiling Point: The boiling point of Vinyl Acetate Monomer is around 72-73°C.

- Solubility: It is highly soluble in organic solvents such as alcohol, acetone, and ether but only sparingly soluble in water.

- Viscosity: Vinyl Acetate Monomer has a relatively low viscosity at room temperature, making it suitable for use in a wide variety of formulations and applications.

Chemical Properties

- Reactivity: Vinyl Acetate Monomer is highly reactive and can undergo polymerization when exposed to heat or light, which is a key property for producing various polymers like polyvinyl acetate (PVA) and ethylene-vinyl acetate (EVA).

- Boiling Point Elevation: When used in polymer solutions, the boiling and melting points can be elevated, which is essential for creating products like coatings, adhesives, and films.

- Flammability: This substance is flammable and can ignite if exposed to open flames or high temperatures, making it necessary to handle it carefully in industrial settings.

- Toxicity: While generally safe in its intended industrial uses, Vinyl Acetate Monomer can cause irritation to the eyes, skin, and respiratory system if mishandled. Proper protective equipment should be used to ensure safety.

These properties make Vinyl Acetate Monomer a crucial chemical in the production of adhesives, films, coatings, and numerous other industrial applications. It plays an essential role in industries such as packaging, textiles, and construction. To ensure its safe and effective use, proper handling, storage, and disposal are vital.

Types of VAM Grades

This material is typically produced in different grades, based on the needs of various industries and specific quality requirements. Most commonly, this grade is divided into a few grades depending on its intended use, such as:

- Industrial Grade: This grade is used for general industrial applications like adhesives, coatings, and plastics. It may contain more impurities than higher-grade options.

- Technical Grade: This grade is used in applications where higher purity is needed, such as for producing certain polymers, but it may still have some minor impurities.

- Research Grade: This grade is typically used in laboratory and research applications where the highest level of purity is required.

Overall, this material is primarily used in industries like adhesives, coatings, and polymer production, and while specialized grades might exist, industrial and technical grades are the most commonly used for various applications.

How to Buy Polyethylene?

- Buy from a reputable and authorized supplier that holds necessary certifications and guarantees quality.

- Compare the prices of these materials in different markets and compare them with the global market price.

- Examine the sales conditions regarding quantity, delivery time, packaging, transportation methods, and payment terms.

- If you intend to import polystyrene from foreign countries, investigate customs and legal regulations and comply with export and import regulations.

- Contact bravopolymer to obtain the most suitable export price based on your conditions.

- After signing the contract, you can place your order.

- Secure and suitable payment methods according to customer preferences are provided by the company.

- Then, the loading stage is completed by selecting and introducing a transport company.

- Necessary documents for customs clearance at the destination city are also provided to customers by bravopolymer.

The largest distributor of polymers in the Middle East