DEA

Diethanolamine (DEA) Diethanolamine (DEA) is exported from Iran to nearby countries such as the UAE, Turkey, and Oman due to its diverse applications in various industries, including detergent production, agriculture, and natural gas processing. The demand for this compound is high in these regions. The price of diethanolamine in Iran is generally lower compared to other countries in the region, such as Turkey and the UAE, because Iran is a major producer of this chemical. For instance, the price of DEA in Iran ranges between $1500 and $1800 per ton (depending on market conditions). In contrast, prices in Turkey and the UAE are higher due to additional transportation costs and import tariffs, often reaching up to $2000 per ton. The lower production costs and favorable geographical location make DEA exports from Iran economically attractive to neighboring countries. However, factors such as currency fluctuations and international sanctions can influence trade dynamics and pricing. Overall, Iran’s competitive pricing and production capacity position it as a key DEA supplier in the region. For more information on DEA prices and ordering methods, you can contact the experts at Petro Nour Mehr Company.

DEA Manufacturers in Iran

In the petrochemical industry of Iran, several companies and production units are engaged in the production of DEA. These companies include:

- Shazand Arak Petrochemical Company

These units are among the largest DEA producers in Iran and play a significant role in supplying domestic needs and exporting this material to global markets.

DEA Manufacturers Worldwide

The most important DEA producers in the world are BASF, Dow Chemical Company, Huntsman Corporation.

Additionally, other companies may be active in DEA production or use it as an intermediate substance in manufacturing processes across the globe.

Applications of DEA

Diethanolamine finds application across several industries due to its versatile properties. Some of the common applications of DEA include:

- Surfactants and Emulsifiers: This material is widely used as a surfactant and emulsifier in various industrial and household products, including detergents, soaps, shampoos, and cosmetics. Its ability to lower surface tension and stabilize emulsions makes it valuable in formulations where mixing water and oil components is necessary.

- Textile Processing: This material is used in textile processing as a wetting agent, dispersant, and dyeing assistant. It helps improve the penetration of dyes and chemicals into fibers, enhances color uniformity, and aids in the even distribution of finishes and coatings on textiles.

- Metalworking Fluids: It is added to metalworking fluids such as cutting fluids, grinding fluids, and rust inhibitors to improve lubrication, cooling, and corrosion resistance during machining and metal processing operations.

- Corrosion Inhibitors: It is employed as a corrosion inhibitor in various applications, including in boiler water treatment, cooling water systems, and metal surface treatments. It forms a protective film on metal surfaces, preventing corrosion and extending equipment lifespan.

- Gas Treating: This material is used in gas processing operations, particularly in the removal of acidic gases such as carbon dioxide (CO2) and hydrogen sulfide (H2S) from natural gas and refinery gases. It reacts with acidic gases to form stable salts, facilitating their removal from gas streams.

- Personal Care Products: This material is utilized in the formulation of personal care products such as lotions, creams, and hair care products as an emulsifying agent, thickener, and pH adjuster. It helps stabilize formulations, improve texture, and adjust the pH of products to match the skin or hair.

- Agrochemicals: It is used in the production of herbicides, pesticides, and fungicides as a formulation aid, dispersant, and stabilizer. It assists in the dispersion and delivery of active ingredients and improves the efficacy and performance of agrochemical formulations.

- Adhesives and Sealants: This material is incorporated into adhesive and sealant formulations to enhance adhesion, flexibility, and moisture resistance. It helps improve the workability and performance of adhesives and sealants in various applications, including construction, automotive, and packaging.

These are just a few examples of the diverse applications of diethylene glycol across industries. Its versatility, solubility, and reactivity make it a valuable chemical in numerous manufacturing processes and formulations.

Storage Conditions for DEA

There are some guidelines for better preservation of its quality:

- It is ideal to keep these materials dry and cool; a temperature of less than 25 degrees Celsius is preferable for storage.

- Keep this material out of direct sunlight and ultraviolet light, since these sources of light may alter its chemical and physical characteristics.

- These substances react with acids and solvents, among other compounds. It is therefore recommended to stay away from direct contact with these kinds of compounds.

- During storage and transportation, ensure that this material is protected from scratches and impacts, as physical damages can lead to changes in its structure and chemical properties.

- Packaging for this grade should be made of suitable material to protect it from environmental changes and reduce the penetration of water and air into the packaging.

- Certain items can need particular storage conditions. Consult the manufacturer’s directions in this situation.

Packaging for DEA

This material is typically packaged in containers that are compatible with its chemical properties and safe for transportation and storage. The packaging for DEA should meet certain requirements to ensure its integrity, safety, and regulatory compliance. Here are some common types of packaging used for this material:

- Drums: It is often packaged in metal drums made of materials such as stainless steel or carbon steel. Drums provide a sturdy and durable packaging option suitable for handling and transportation of bulk quantities of this material. They typically come in various sizes ranging from 55-gallon (200-liter) drums to larger capacities.

- Intermediate Bulk Containers (IBCs): IBCs, also known as tote tanks or bulk containers, are large, rigid containers made of materials such as high-density polyethylene (HDPE) or composite materials. They offer a cost-effective and space-efficient packaging solution for transporting and storing intermediate quantities of this material.

- Cans/Bottles: This material may be packaged in smaller cans or bottles made of metal or plastic for retail or consumer applications. These containers are typically used for packaging DEA-based products such as household cleaners, detergents, and personal care products.

Regardless of the type of packaging used, it is important to ensure that the containers are properly sealed, labeled, and compliant with relevant regulatory standards for the safe handling, transportation, and storage of this material. Additionally, proper safety precautions should be followed when handling and storing this material to prevent exposure and ensure the integrity of the packaging.

DEA Characteristics

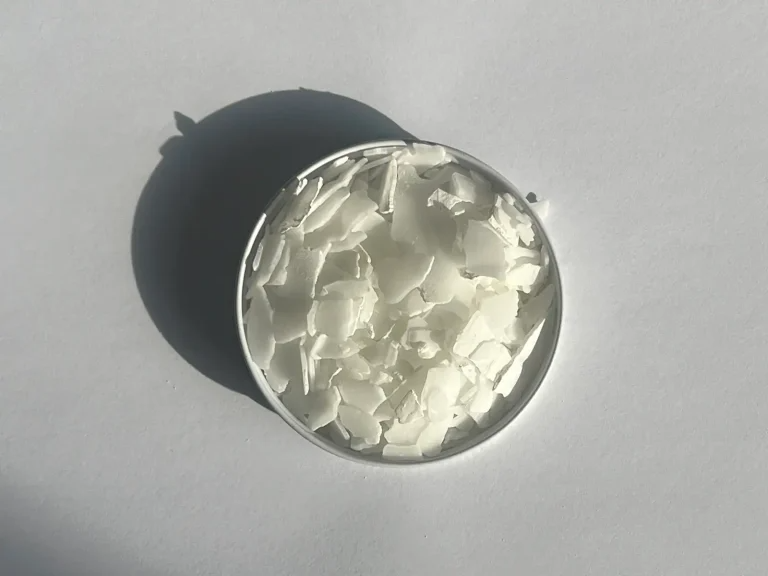

Diethanolamine (DEA or DEOA) is a colorless and viscous liquid or a white solid crystal with the chemical formula C4H11NO2, functioning as both a secondary amine and a diol. DEA has a faint odor similar to rotten fish or ammonia. It is highly soluble in water and ethanol, and slightly soluble in ether and benzene. DEA, like all ethanolamines, is exclusively produced by the reaction of ethylene oxide with excess ammonia. DEA is a hydrophilic liquid used as a surfactant and a corrosion inhibitor, and for removing hydrogen sulfide from natural gas.

This compound is widely utilized to prepare diethanolamides and salts of diethanolamine with long-chain fatty acids. Additionally, it is extensively used in textile processing, industrial gas purification to remove acidic gases, as a corrosion inhibitor in metalworking fluids, and in the preparation of agricultural chemicals. This organic compound has a molecular weight of 387.59 gr/mol.

Advantages and Disadvantages of DEA

Below are the advantages and disadvantages of this material:

Advantages of Diethanolamine:

- Versatile Surfactant: This material is widely used as a surfactant, aiding in the formation of emulsions and improving the spreadability of liquids. This makes it valuable in cleaning products, shampoos, and cosmetics.

- Corrosion Inhibition: It acts as an effective corrosion inhibitor, which is beneficial in metalworking fluids and other industrial applications to prevent rust and degradation of metal surfaces.

- Gas Treatment: This material is used in the removal of acidic gases like hydrogen sulfide and carbon dioxide from natural gas and refinery gas streams, improving the quality and safety of these gases.

- Textile Processing: In the textile industry, DEA is employed to enhance the softness and processability of fabrics, contributing to higher quality textile products.

- Chemical Intermediary: It serves as an intermediate in the synthesis of various chemical compounds, including diethanolamides, which are used in a wide range of applications from personal care products to industrial cleaning agents.

Disadvantages of Diethanolamine:

- Health Hazards: This material can be harmful if inhaled, ingested, or absorbed through the skin. It is known to cause irritation to the skin, eyes, and respiratory system. Prolonged exposure can lead to more serious health issues such as liver and kidney damage.

- Toxicity: This material has been identified as a potential carcinogen. Studies have shown that long-term exposure to this material and its derivatives can increase the risk of cancer in laboratory animals, raising concerns about its safety in consumer products.

- Environmental Impact: It is not readily biodegradable and can pose environmental risks if released into waterways. It can be toxic to aquatic life, leading to potential environmental contamination and ecological disruption.

- Regulatory Restrictions: Due to its health and environmental risks, the use of this material is subject to regulatory restrictions and guidelines. Manufacturers must comply with safety regulations, which can increase production costs and limit its usage in certain applications.

- Reactivity: This material can react with certain chemicals, forming potentially harmful by-products. For instance, it can react with nitrosating agents to form N-nitrosodiethanolamine (NDELA), a known carcinogen. This requires careful handling and formulation to avoid hazardous reactions.

This material is a versatile chemical with several industrial and commercial applications due to its properties as a surfactant, corrosion inhibitor, and chemical intermediary. However, its use is tempered by significant health, safety, and environmental concerns, requiring careful handling and adherence to regulatory standards.

Physical and Chemical Properties of DEA:

Diethanolamine is a compound used in various industrial applications, including as a surfactant, emulsifier, and in the production of detergents, textiles, and personal care products. Here are some of its physical and chemical properties:

Physical Properties:

- Appearance: It is typically a clear, colorless to pale yellow liquid.

- Solubility: This material is soluble in water and many organic solvents.

- pH: In water, DEA typically exhibits a slightly alkaline pH.

Chemical Properties:

- Amphiphilic Nature: This material possesses both hydrophilic (water-attracting) and lipophilic (fat-attracting) properties, making it useful as an emulsifier and surfactant.

- Amine Group: DEA contains two hydroxyl groups and one amino group, which can undergo various chemical reactions, such as amidation, esterification, and alkylation.

- Reactivity: DEA can react with acids to form salts and with alkyl halides to form alkylated amines.

- Basicity: DEA is a weak base and can undergo protonation to form diethanolammonium salts.

- Hydrolysis: Under certain conditions, DEA can undergo hydrolysis to produce ethanolamine and other products.

It’s important to handle DEA with care as it can be corrosive and may cause irritation upon contact with skin or eyes. Additionally, its use and disposal should adhere to safety and environmental regulations.

Types of DEA grades:

Diethanolamine is available in different grades depending on its purity and intended application. Some common types of DEA grades include:

- Technical Grade: This grade is commonly used in industrial applications where high purity is not critical. It may contain impurities and is typically used in applications such as metalworking fluids, corrosion inhibitors, and agricultural chemicals.

- Cosmetic Grade: DEA used in cosmetics and personal care products must meet stringent purity requirements to ensure safety for use on the skin and hair. Cosmetic grade DEA undergoes additional purification steps to remove impurities and contaminants.

- Pharmaceutical Grade: DEA used in pharmaceutical products must meet even higher purity standards compared to cosmetic grade DEA. It undergoes extensive purification and testing to ensure compliance with pharmaceutical regulations and standards for use in pharmaceutical formulations.

- Food Grade: DEA intended for use in food products must meet strict regulations set by food safety authorities. It undergoes thorough purification to ensure it is free from contaminants and safe for use in food applications, such as in food additives and processing aids.

- Industrial Grade: This grade of DEA is used in various industrial applications where specific purity requirements need to be met but are not as stringent as those for pharmaceutical or cosmetic grades. It finds applications in products like detergents, cleaners, and chemical intermediates.

Each type of DEA grade has its own specifications and quality standards to meet the requirements of its intended application and industry regulations.

How to Buy Polyethylene?

- Buy from a reputable and authorized supplier that holds necessary certifications and guarantees quality.

- Compare the prices of these materials in different markets and compare them with the global market price.

- Examine the sales conditions regarding quantity, delivery time, packaging, transportation methods, and payment terms.

- If you intend to import polystyrene from foreign countries, investigate customs and legal regulations and comply with export and import regulations.

- Contact bravopolymer to obtain the most suitable export price based on your conditions.

- After signing the contract, you can place your order.

- Secure and suitable payment methods according to customer preferences are provided by the company.

- Then, the loading stage is completed by selecting and introducing a transport company.

- Necessary documents for customs clearance at the destination city are also provided to customers by bravopolymer.

The largest distributor of polymers in the Middle East