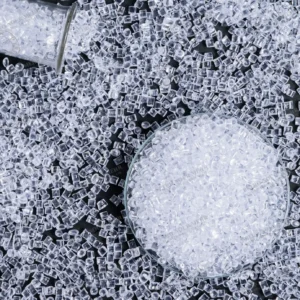

Polystyrene (PS)

Polystyrene is a type of thermoplastic polymer primarily composed of styrene. Due to its properties such as lightweight, rigidity, and good resistance to impacts and moisture, it finds wide applications in various industries. One of the main applications of PS is in the packaging industry. Packaging made of this polymer material is well-suited for packaging sensitive and fragile products due to its lightweight and resistance. Additionally, in the automotive industry, polystyrene is used for making interior parts of vehicles due to its lightweight nature and impact resistance. Moreover, expanded polystyrene (EPS) foam is another important application of this material. This foam is used for thermal and sound insulation in buildings, packaging, and making containers for temperature preservation. Additionally, high-impact polystyrene (HIPS) is used in various industries where increased strength and impact resistance are required. This type of polystyrene is utilized as decorative materials in packaging, toy manufacturing, and similar applications. These PS will be exported with the HS code 39039000. Exporting this material to various countries with the best price has been one of the achievements of Petro Nour Mehr Company in recent years. For more accurate information regarding prices or purchasing the product, it is better to contact the sales department of Petro Nour Mehr Company.

HIPS

HIPS is commonly used in injection molding and extrusion to make items like refrigerator liners, door panels.

Polystyrene Manufacturers in Iran

In the petrochemical industry of Iran, several companies and production units are engaged in the production of PS. These companies include:

- Takht-e-Jamshid Petrochemical Company

- Tabriz Petrochemical Company

These units are among the largest PE producers in Iran and play a significant role in supplying domestic needs and exporting this material to global markets

Applications of Polystyrene

Polystyrene is a versatile polymer with many applications due to its low cost, ease of molding, and insulating qualities. Here are some of its most common applications:

- Packaging: protective foam packaging for electronics, food containers, and disposable tableware.

- Construction: insulation boards, lightweight fill materials, and decorative moldings.

- Consumer Products: household items, toys, and stationery.

- Electronics: casings, housings, and electrical insulators.

- Medical: packaging for medical devices and labware like petri dishes.

- Automotive: Interior components and vehicle insulation.

- Arts and Crafts: Craft materials, signage, and model making.

- Industrial: patternmaking and prototyping.

- Recycling: Recycled into products like picture frames and insulation sheets.

Polystyrene is widely used due to its moldability and insulation properties, though its environmental impact is a concern.

Storage Conditions for Polystyrene

Proper storage conditions for polystyrene are essential to maintain its properties and prevent degradation. Here are the key guidelines:

- Temperature: Store PS in a cool, dry place. Avoid exposure to extreme temperatures (both high and low). Optimal storage temperature is typically between 15-25°C (59-77°F).

- Humidity: Keep PS away from moisture. High humidity can affect the material’s properties over time. Store it in an environment with low humidity.

- Light: Avoid prolonged exposure to direct sunlight or UV light, as it can cause degradation and discoloration. Store PS in a dark or covered area.

- Oxygen and Ozone: Minimize exposure to oxygen and ozone, as they can cause oxidation and degradation of the material.

- Packaging: Keep PS in its original packaging if possible, or use airtight and moisture-proof containers.

- Stacking: Avoid heavy stacking that might cause deformation. If stacking is necessary, ensure that the weight is evenly distributed.

- Cleanliness: Store PS in a clean environment, free from dust, dirt, and other contaminants.

- Avoid Mechanical Stress: Handle PS with care to avoid scratches, cuts, or other mechanical damage.

- Chemical Exposure: Keep PS away from chemicals, solvents, and other materials that could cause degradation.

By following these storage guidelines, you can ensure that your polystyrene remains in good condition for its intended use.

Packaging for Polystyrene

For packaging and exporting polystyrene granules, various methods can be utilized depending on environmental conditions, product needs, and facilitating transportation for export. Below are some common methods for packaging and exporting these polymer granules:

- Packaging in Jumbo Bags: This is a common method for packaging PS granules, where the granules are packed into large bags with varying capacities (usually between 500 to 2000 kilograms). These bags not only protect the product from contamination and moisture but are also suitable for road, sea, and air transport.

- Packaging in Small Bags: In this method, the polymer granules are packed into smaller bags with a capacity of around 25 to 50 kilograms. These bags are used for retail stores and local markets or for small shipments.

- Using Pallets: These polystyrene granules are usually packed on large pallets. This method is used for transportation.

Attention to international packaging standards, labeling, and transportation conditions can influence the choice of appropriate packaging and exporting methods for polystyrene granules. Additionally, it is important to emphasize protecting the product from shocks, moisture, and environmental damage during transportation.

Physical and Chemical Properties of Polystyrene

This material is a versatile polymer with the following key properties:

Physical Properties

- Density: ~1.04–1.06 g/cm2 for solid, lower for foam.

- Appearance: Clear or transparent; foam form is opaque.

- Transparency: Naturally transparent in solid form.

- Thermal Properties: glass transition temperature around 100°C; low thermal conductivity, especially in foam form.

- Mechanical Properties: hard and brittle; low elasticity and impact resistance.

- Electrical Properties: Excellent electrical insulator with a dielectric constant of around 2.6.

Chemical Properties

- Composition: Made from styrene monomers.

- Chemical Resistance: Resists water, weak acids, and bases; vulnerable to organic solvents.

- Solubility: insoluble in water; soluble in aromatic hydrocarbons and chlorinated solvents.

- Flammability: Highly flammable; produces toxic fumes when burned.

- Environmental Stability: Degrades under UV light; not biodegradable.

Despite its useful properties, polystyrene poses environmental challenges due to its persistence and flammability.

To produce polystyrene, styrene is polymerized into a liquid form at high temperatures along with catalysts and polymerization initiators. Then, this liquid is molded into various shapes and solidified upon cooling.

Types of Polystyrene Grades:

Polystyrene, a versatile thermoplastic polymer, is available in various grades tailored to specific applications and processing requirements. Some common types of polystyrene grades include:

- General-Purpose Polystyrene (GPPS): GPPS is a transparent and rigid form of polystyrene widely used in applications such as packaging, food containers, disposable cutlery, and cosmetic packaging. It offers excellent clarity and surface gloss, making it suitable for applications where visual appeal is important.

- High-Impact Polystyrene (HIPS): HIPS is a modified form of polystyrene that incorporates rubber or elastomer additives to improve impact resistance and toughness. It retains the clarity of GPPS while offering enhanced durability, making it suitable for applications such as refrigerator liners, electronics packaging, and toys.

- Expandable Polystyrene (EPS): EPS is a lightweight and rigid foam derived from polystyrene beads through a process of expansion and molding. It is commonly used as insulation material in construction, packaging, and cushioning applications due to its low thermal conductivity and shock-absorbing properties.

- Extruded Polystyrene (XPS): XPS stands for Extruded Polystyrene, which is a type of rigid foam insulation material commonly used in construction, packaging, and other applications. XPS is made from polystyrene resin combined with additives and a blowing agent.

These are just a few examples of the various types of polystyrene grades available, each designed to meet specific performance requirements and application needs across different industries.

Comparison between grades of polystyrene:

Polystyrene (PS) is available in various grades, each tailored for specific applications. Here’s a comparison between different grades of polystyrene:

- General-Purpose Polystyrene (GPPS):

- GPPS is the most common and widely used grade of poly….

- It offers good clarity, rigidity, and processability, making it suitable for applications such as packaging, disposable cutlery, and CD cases.

- However, GPPS may be brittle and prone to impact damage compared to other grades.

- High-Impact Polystyrene (HIPS):

- HIPS is modified with rubber or elastomers to enhance impact resistance.

- It retains the clarity and processability of GPPS while offering improved toughness and resistance to impact, making it suitable for applications where durability is essential, such as refrigerator liners, toys, and electronics packaging.

- HIPS is more ductile and less brittle than GPPS, making it less prone to cracking or shattering upon impact.

- Expandable Polystyrene (EPS):

- EPS is a lightweight, cellular plastic material produced by expanding polystyrene beads.

- It is known for its excellent thermal insulation properties, low density, and shock-absorbing characteristics.

- EPS is widely used in packaging, construction (insulation boards, lightweight concrete), and food service (foam cups, food containers) industries.

- Extruded Polystyrene (XPS):

- XPS is a dense, closed-cell foam with high compressive strength and moisture resistance.

- It is commonly used for thermal insulation in buildings, as it provides excellent thermal performance and moisture resistance.

- XPS is also used in packaging, crafts, and model making due to its smooth surface and ease of cutting and shaping.

Overall, the choice of polystyrene grade depends on the specific requirements of the application, including mechanical properties, clarity, thermal insulation, and cost considerations.

How to Buy Polyethylene?

- Buy from a reputable and authorized supplier that holds necessary certifications and guarantees quality.

- Compare the prices of these materials in different markets and compare them with the global market price.

- Examine the sales conditions regarding quantity, delivery time, packaging, transportation methods, and payment terms.

- If you intend to import polystyrene from foreign countries, investigate customs and legal regulations and comply with export and import regulations.

- Contact bravopolymer to obtain the most suitable export price based on your conditions.

- After signing the contract, you can place your order.

- Secure and suitable payment methods according to customer preferences are provided by the company.

- Then, the loading stage is completed by selecting and introducing a transport company.

- Necessary documents for customs clearance at the destination city are also provided to customers by bravopolymer.

The largest distributor of polymers in the Middle East